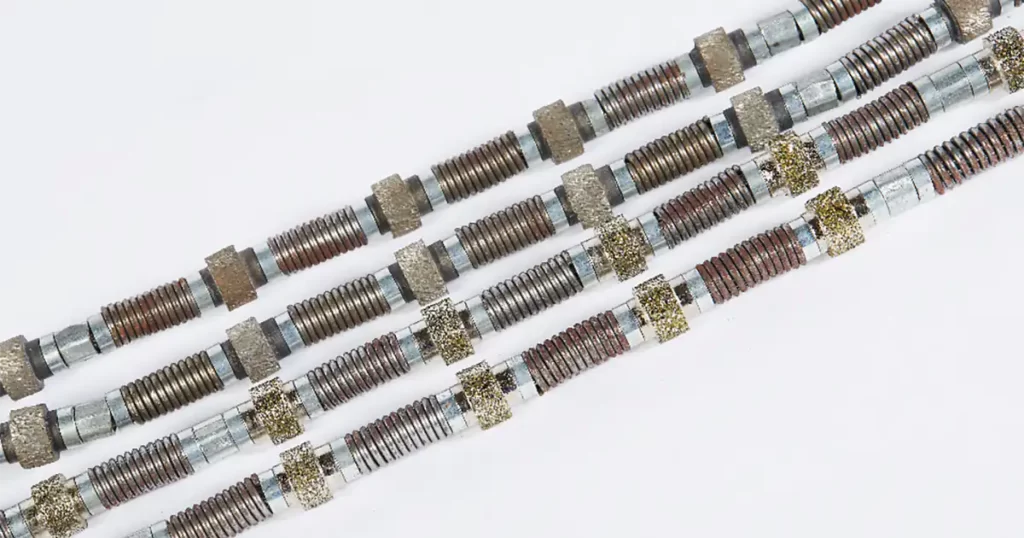

In order to ensure that the diamond wire saw can be maintained and used correctly, a set of accessories must be equipped, including wire rope cutting pincer, manual hydraulic crimping pincer, lever-type hydraulic pincer, the assembly workbench of the diamond wire saw, crimping jaw of connectors, etc.

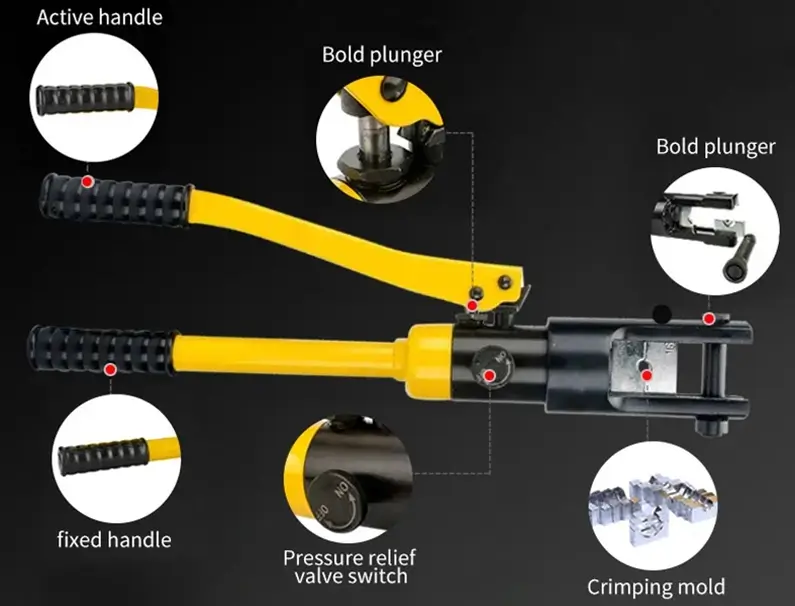

Manual Hydraulic Crimping Pincer

The manual hydraulic crimping pincer is actually a standard hydraulic tool, which is mainly used for the crimping combination between wires and terminal blocks. Because it is a standard hydraulic tool, it must be equipped with a special crimping jaw, after that, it can be used to connect the diamond wire saw and make it a closed cutting loop.

Structure of Manual Hydraulic Crimping Pincer

The manual hydraulic crimping pincer is the most commonly used crimping tool that uses static friction to connect the wire rope and the connectors. It has the advantages of a simple structure, enough joint pressure can be applied to the connectors and flexible and convenient operation. The manual hydraulic crimping pincer can be used to connect various structures of diamond wire saws such as spring type, plastic injection type and rubber injection type, as well as various joints requiring static friction. During stone mining and processing, manual hydraulic crimping pincers with different pressure values are required according to different uses of diamond wire saws. For example, the diamond wire saw used to connect and cut marble needs to be equipped with a manual hydraulic crimping pincer that can provide 100kN pressure. When connecting the diamond wire saw used to cut granite, the manual hydraulic crimping pincers that can provide 200kN pressure need to be used.

Technical Parameters of Manual Hydraulic Crimping Pincer

The manual hydraulic crimping pincers are generally used for intermediate connection and terminal sealing during power, lighting and cable installation. There is a quick device inside which can be adjusted automatically. According to the different uses of crimping materials/subjects, after using different crimping jaws, it can be divided into manual hydraulic crimping pincers for pressing aluminum, copper and steel connectors. When connecting the wire rope and connectors, the manual hydraulic crimping pincer with sufficient pressure shall be used to press the steel connectors.

| Structure and Technical Parameters of KYQ Series Manual Hydraulic Crimping Pincers | ||||||

|---|---|---|---|---|---|---|

| Model | KYQ-120A | KYQ-240A | KYQ-300A | FYQ-400 | FYQ-630 | |

| Crimping Range/mm | Aluminum | 10-120 | 16-240 | 16-300 | 150-400 | 150-630 |

| Copper | 10-120 | 16-150 | 16-240 | 150-300 | 150-500 | |

| Maximum Working Pressure/kN | 120 | 160 | 200 | 250 | 250 | |

| Maximum Working Stroke/mm | 14 | 22 | 22 | 22 | 22 | |

| Overall Dimension/mm*mm*mm | 400*105*65 | 460*110*68 | 510*135*80 | Disconnect | Disconnect | |

| Weight/kg | 2.5 | 3.4 | 4.5 | |||

| Supporting Hexagonal Crimping Mold/Jaw | 10/16/25/35 | 16/25/35/50/70 | 16/25/35/50/70 | |||

| 50/70/95/120 | 95/120/150/185/240 | 95/120/150/185/240 | ||||

| Hydraulic Oil Model | 32# Machine Oil | |||||

How to Use Manual Hydraulic Crimping Pincer

According to the above structural schematic diagram of the manual hydraulic crimping pincer, its operation steps and working principle are as follows:

According to the diameter of the connectors, prepare the crimping mold/jaw of the corresponding size, and move the handle to make the oil pump core rise, at this time, the oil inlet valve opens to feed oil, when the handle is pressed down, the oil outlet valve opens to discharge oil, and the pressure oil pushes the large and small pistons to move, forcing the return spring to compress so that the pressure mold/jaw moves forward. When the two crimping mold/jaw contact slightly, the pressure should be stopped to prevent damage to the oil pressure system. After the crimping is in place, loosen the oil return screw (not too much) to open the oil return valve. Under the action of the oil return spring, the hydraulic oil returns to the oil storage pipe, and the crimping mold/jaw is released to the initial position.

How to Repair and Maintain Manual Hydraulic Crimping Pincer

Because the manual hydraulic crimping pincer is a relatively precise hydraulic tool, the following points must be paid attention to when crimping the connectors of the diamond wire saw:

- Stop crimping when the two crimping molds/jaws contact, otherwise the manual hydraulic crimping pincer will be damaged.

- Don’t knock the crimping molds/jaws and pincer during use to avoid deformation and damage.

- It is not allowed to carry out the crimping operations in muddy water or with sediment between the crimping molds/jaws and the connectors, as well as in acid and alkali corrosive gas environments;

- Regularly check the pressure oil in the hydraulic crimping pincer, and ensure that there is sufficient pressure oil in the hydraulic crimping pincer that meets the requirements after filtration.

- The manual hydraulic crimping pincer shall be kept by a specially-assigned person.

- After use, it shall be washed with clean water and stored dry.

- It shall not be knocked or collided. It is strictly prohibited to pressurize blindly after the operation.

- The oil return screw must be loosened during storage.

- When it is not used for a long time, the hydraulic crimping pincer should be wiped clean, and the surface should be coated with anti-rust grease for storage.

- The structure of the manual hydraulic crimping pincer is tight and cannot be disassembled at will. If it needs to be disassembled, it must be carried out in a clean and dry place to prevent dust and sundries from mixing into the internal structure of the hydraulic crimping pincer.

- After long-term use, the hydraulic crimping pincer will slightly leak oil, causing pressure oil to decrease. At this time, unscrew the fixed handle and the tail pipe screw, swing the handle, press a small amount of residual pressure oil into the cylinder, and then add some pressure oil. The added pressure oil must be filtered through the 200# filter screen. When the pressure oil is replenished to fill the oil cylinder, unscrew the tailpipe screw again without tightening it, and then open the oil return screw. After the pressure oil overflows slightly and the air in the system is discharged, tighten the tailpipe screw to wipe up the spilled oil. After installing the fixing handle, the hydraulic crimping pincer can continue to be used.

- If the valve is poorly sealed and air enters the hydraulic oil circuit, the piston will move forward and backward.

- If the large spring is broken or deformed, the piston will not be dislodged.

- In case of serious oil leakage at the piston, plunger and oil return screw, the hydraulic crimping pincer shall be disassembled and cleaned, the damaged parts shall be replaced, and the air shall be removed by adding pressure oil. After reassembly, the hydraulic crimping pincer can continue to be used.

Manual Mechanical Crimping Pincer

In the early days when spring-type diamond wire saw was used in marble mines, a large number of copper connectors were used to connect diamond wire saws. At that time, a large number of manual mechanical crimping pincers were also used. The structure of the manual mechanical crimping pincer is more simple. The clamping part of the jaw is made into three butting circular molds/jaws with different diameters. According to the pressing sequence from large to small, the connector and the wire rope are crimped together. Although the copper connectors are usually relatively soft, the cut stone is mostly soft marble, limestone or travertine, and the diamond wire saw with a spring structure is used, so the manual mechanical crimping pincer can basically meet the using requirement.

At present, this manual mechanical crimping pincer is still used in marble stone mines. The advantages of manual mechanical crimping pincers are their simple structure and low price. The disadvantage is that they are only suitable for crimping copper connectors. For some mechanical pincers with replaceable molds/jaws, after the molds/jaws are worn, the pincers can continue to be used as long as the molds/jaws are replaced. If the mold/jaw is integrated with the pincer, the manual crimping pincer can only be scrapped after wear.

Lever Type Hydraulic Crimping Pincer

The structure, working principle and use of the lever type hydraulic crimping pincer are similar to the manual hydraulic jack. It is composed of jaw, oil cylinder, pump, pressure rod, connecting hose and other parts.

Different from the manual hydraulic crimping pincer, the hydraulic crimping pincer can generally be installed with 2 to 3 different size molds/jaws, which can be used to connect the connectors and the wire rope firmly and reliably according to the order of using size from big to small. Because the lever is relatively long and the pressure cylinder assembly can be placed firmly on the ground, the operation of the lever-type hydraulic crimping pincer is relatively labor-saving, the labor intensity of the operator is low, and the connection of the diamond wire saw is reliable.

Compared with the manual hydraulic crimping pincer, the lever type hydraulic crimping pincer’s disadvantages are the large size and heavy weight, and inconvenient to carry. The lever-type hydraulic crimping pincer also has pressure specifications of 100kN and 200kN, or an accessory with adjustable pressure value is installed to meet the requirements of different engagement pressures.

In order to carry the lever type hydraulic crimping pincer conveniently, people have developed a portable lever-type hydraulic crimping pincer. The advantages of portable lever-type hydraulic crimping pincer are that the cylinder volume and piston diameter are relatively bigger, and compared with the manual hydraulic crimping pincer, it is more labor-saving when crimping. The pressure jaw is installed together with the hydraulic cylinder block, and the device is relatively small and easy to carry. The pressure cylinder is installed with a support bracket, which can be firmly placed on the ground and is more stable and reliable during operation.

Worktable for Assembling Spring Type Diamond Wire Saw

Diamond wire saw manufacturers and soft stone mining enterprises often use spring diamond wire saw assembly worktables for efficient assembly and repair of diamond wire saws with spring structure.

Its working principle is basically the same as that of lever type hydraulic crimping pincer. The difference is that the pressure oil entering the pressure cylinder is not provided by the manual pressure pump, but by the electric hydraulic pump station. On the box-type worktable, a set of mechanical preloading device is added for preloading the spring before connecting the spring type diamond wire saw. The drive of the hydraulic cylinder is controlled by the foot control switch, which ensures the connection quality of the diamond wire saw.

The operation process of the worktable is to first thread 3~5 sets of diamond beads, springs and washers into the wire rope according to the requirements, and one end is fixed by the fixed ring pressed on the wire rope. According to the requirements of pre-compression, use the caliper handle to pre-press the diamond bead assembly penetrating into the wire rope at the appropriate position of the wire rope, and at the same time, place the fixed ring at the other end of the assembly in the crimping mold of the cylinder jaw to implement the compression connection. According to the different structures of the diamond wire saw, for example, the number of diamond beads on the diamond wire saw per meter is different, or the number of diamond beads in each group is different, the operation position of the caliper handle can be adjusted to ensure that the assembled diamond wire saw has appropriate preload.

In marble mines where a large number of spring-type diamond wire saws are used, parts such as wire ropes, diamond beads, springs and washers can be purchased directly. According to the actual requirements of mining, diamond wire saws of different lengths can be assembled using the assembly worktable. In mining operations, the quickest wear of the spring-type diamond wire saw is the wire rope. Sometimes the wire rope has been broken and can no longer be used, but the diamond beads also have a certain service life. The collected diamond beads can be classified according to the diameter, and the new wire rope can be used to reassemble the diamond wire saw that can continue to use, so as to maximize the service life of the diamond beads. Repairing and using the used diamond beads also requires assembling the worktable.

Wire Cutting Plier

The diamond wire saw needs to be cut and reconnected frequently in the process of use, so it must be equipped with appropriate wire cutters for cutting the wire rope. The requirement for cutting the wire rope is that the cutting surface of the wire rope must be flush, the section must be perpendicular to the wire rope axis, and the thin wire rope that constitutes the wire rope cannot be loose, so as to ensure that the wire rope can be easily inserted into the connector, and maintain a joint surface of sufficient length with the connector to ensure a firm connection.

Therefore, only crescent-shaped cutting pliers with sharp edges can meet the above requirements. The length of the wire cutting piler handle should be in the range of 50~70cm, which can meet the requirements for cutting force. If the handle length is too short, it is hard to cut the wire rope well. If the handle length is too long, it will cause the weight of whole wire cutting plier to be too heavy, which is not convenient for operation and use.

Crimping Jaw

In the early stage, the crimping jaw(or called crimping mold) was mostly made with a round shape, and at present, the hexagon shape crimping jaw is the most used. Because the connectors of diamond wire saws are mostly made of steel, the crimping jaw is required to have relatively high strength, hardness and toughness.

The crimping jaw for crimping aluminum or copper connectors sold on the market is not suitable for the crimping of diamond wire saws. The crimping jaw for crimping steel connectors must be selected to ensure the crimping quality and service life of the jaw. According to the different diameters of the connectors, the appropriate and matching size of the crimping jaw should be selected. If the connector is not matched with the crimping jaw, the quality of the connection between the diamond saw and the connector will be reduced, or the connector is not firmly crimped, and it is easy to loosen and break the wire rope, which may also cause the deformation of the connection part of the connector, resulting in the broken strand of the wire rope, which will also cause the rope breaking accident.