The diamond tool processing procedures for ceramic tiles mainly include: determining the thickness of the tiles, polishing the surface of the tiles, edging the tiles, cutting and chamfering the tiles.

Common types of ceramic tiles include polished tiles, glazed tiles, paving stones, antique tiles, imitation stone tiles, etc. Different tiles have different production processes and different diamond abrasive tools and equipment.

Dymend has developed corresponding diamond tools according to the production of different tiles.

Diamond Calibrating Roller

The diamond calibrating roller is mainly used in the production of polished tiles and is the most commonly used tool in the process of calibrating and achieving a uniform thickness on ceramic tiles’ surfaces before polishing. The cutter segment formula and production process developed by Dymend make the diamond hob have good sharpness, service life, stable quality and processing effect, which can effectively reduce production energy consumption and working noise.

| Specifications of Diamond Calibrating Roller | ||||||

|---|---|---|---|---|---|---|

| Description | Diameter(mm) | Length(mm) | Spirals | Segment Size | Grit | Note |

| Diamond Calibrating Roller for Polished Tiles | Φ180 – Φ320 | 300(295) | 5/6/7/8 | 6*10 9*12 9*14 9*15 |

30#, 40#, 50#, 60#, 70#, 80#, 100#, 120#, 140#, 170# | Special Specifications Can Be Customized |

| 400(395) | ||||||

| 500(495) | ||||||

| 600(595) | ||||||

| 645(585) | ||||||

| 800(680/795) | ||||||

| 800(740/795) | ||||||

| 995(935) | ||||||

| 1000(995) | ||||||

| 1200(1135/1195) | ||||||

| 1600(1580) | ||||||

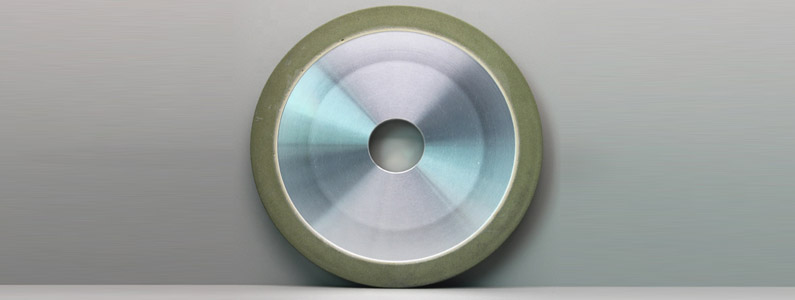

Diamond Cylindrical Wheel

After the diamond calibrating roller scrapes the polished tile to calibrate the thickness, it needs to be made rough cutting with the diamond cylindrical wheel. Colleagues, diamond cylindrical wheels can also replace the diamond calibrating rollers. When working, the high-efficiency cutting action produced by the revolution of the equipment motor and the rotation of the cylindrical wheel makes the surface of the brick more smooth and delicate, which can improve the speed of subsequent polishing, reduce the consumption of polishing tools, such as diamond Fickert, and reduce the re-polishing rate. The diamond cylindrical wheel developed by Dymend has the characteristics of high cutting efficiency, good surface flatness of the ceramic tiles, and fine and uniform cut marks.

Continuous Rim Diamond Cylindrical Wheel

The continuous rim diamond cylindrical wheel adopts the whole sintering process and the continuous rim structure of the segment, which makes the surface gloss of the ceramic tile more delicate during processing.

| Specifications of Continuous Rim Diamond Cylindrical Wheel | ||||||

|---|---|---|---|---|---|---|

| Description | Diameter(mm) | Segment Length(mm) | Segment Height(mm) | Segment Width(mm) | Grit | Note |

| Continuous Rim Diamond Cylindrical Wheel for Polished Tiles | Φ150 | 80 | 40 | 10 | 60#, 80#, 100#, 120#, 140# | Special Specifications Can Be Customized |

| 90 | 90 | 10 | ||||

| Φ180 | 60 | 60 | 10/12 | |||

| 72 | 60 | 10/12 | ||||

| Φ200 | 24 | 24 | 10 | |||

| 40 | 40 | 10 | ||||

| 60 | 58 | 10 | ||||

Segmented Diamond Cylindrical Wheel

The segmented diamond cylindrical wheel has the characteristics of good sharpness and high cutting efficiency.

| Specifications of Segmented Diamond Cylindrical Wheel | ||||||

|---|---|---|---|---|---|---|

| Description | Diameter(mm) | Length(mm) | Spirals | Segment Size | Grit | Note |

| Segmented Diamond Cylindrical Wheel for Polished Tiles | Φ184 | 64 | 12 | 40*8*13 | 60#, 80#, 100#, 120#, 140# | Special Specifications Can Be Customized |

| Φ200 | 40 | 16 | 20*6*10 | |||

| 45 | 16 | 25*6*10 | ||||

| 60 | 8 | 40/36*9*10 | ||||

| Φ208 | 60 | 8 | 40.8/36*9*14 | |||

Diamond Satellite Wheel

The function of the diamond satellite wheel is similar to that of the cylindrical wheel, and it is used for rough grinding after the ceramic adobe is flattened and thickened. The high-efficiency grinding effect produced by the revolution of the grinding motor and the rotation of the diamond satellite wheel during work makes the surface of the ceramic tiles more smooth and delicate, which can improve the polishing speed, reduce the consumption of polishing abrasives, and reduce the re-polishing rate. The diamond satellite wheel developed by Dymend has the characteristics of high grinding efficiency, good surface flatness of the tiles, and fine and uniform grinding marks.

| Specifications of Diamond Satellite Wheel | ||||

|---|---|---|---|---|

| Description | Diameter(mm) | Segment Size | Grit | Note |

| Diamond Satellite Wheel for Ceramic Tiles | Φ100 | 20*20 15*20 15*15 |

36#, 46#, 60#, 70#, 80#, 100#, 120# | Special Specifications Can Be Customized |

| Φ150 | ||||

| Φ175 | ||||

| Φ200 | ||||

Diamond Fickert

Diamond Fickert is used for surface grinding of polished tiles, suitable for automatic polishing line machinery, and used to replace traditional silicon carbide abrasives, with the following characteristics.

- Long service life, 80 to 150 times longer than traditional silicon carbide abrasives.

- The grinding efficiency is increased by more than 50%, the electricity consumption of the polishing spindles is reduced by more than 40%, and the polishing efficiency is increased by more than 20%.

- Reduce polishing spindle maintenance cost and belt wear cost by more than 30% during polishing.

- Compared with traditional silicon carbide abrasive, the discharge of abrasive waste residue can be reduced to less than 1%, and the amount of waste residue produced by diamond grinding Fickert is almost negligible.

- It can significantly reduce the labor intensity of workers, reduce the frequency of abrasive tool replacement, and save labor costs.

- It can reduce the total amount of transportation and save social resources such as energy and logistics.

According to the different bonding agents, it can be divided into metal-bond diamond Fickert and resin-bond diamond Fickert.

Metal-Bond Diamond Fickert

Metal-bonded diamond Fickert is used for rough and medium grinding of the surface of the ceramic tiles. The latest formulation system, production process and structural design developed by Dymend ensure the perfect performance of diamond grinding blocks in terms of grinding efficiency, grinding effect, advancement, economy and reliability.

| Specifications of Metal-Bond Diamond Fickert | |||||

|---|---|---|---|---|---|

| Description | Length Type(mm) | Dimension(mm) Length*Width*Height |

Grit | Application | Note |

| Metal-Bond Diamond Fickert | L140 | 133*56*12 | 46#, 60#, 80#, 100#, 120#, 150#, 180#, 240#, 320#, 400# | Rough and Medium Grinding for Polished Tiles | Special Specifications Can Be Customized |

| L140 | 133*56*15 | ||||

| L170 | 164*62*12 | ||||

| L170 | 164*62*15 | ||||

| Resin-Metal-Bond Diamond Fickert | L140 | 133*56*12 | 300#, 400#, 500#, 600#, 800#, 1000# | Fine Grinding | |

| L140 | 133*56*15 | ||||

| L170 | 164*62*12 | ||||

| L170 | 164*62*15 | ||||

Resin-Bond Diamond Fickert

The resin-bond diamond Fickert is used for further fine polishing and fine finishing of ceramic polished tiles, which can continue to improve the surface gloss, and has the characteristics of good grinding and polishing effect, long service life and competitive cost.

| Specifications of Resin-Bond Diamond Fickert | |||||

|---|---|---|---|---|---|

| Description | Length Type(mm) | Dimension(mm) Length*Width*Height |

Grit | Application | Note |

| Resin-Bond Diamond Fickert | L140 | 132*58*12 | 120#, 150#, 180#, 240#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500# | Fine Grinding and Polishing for Polished Tiles | Special Specifications Can Be Customized |

| L140 | 132*58*15 | ||||

| L170 | 164*62*12 | 120#, 150#, 180#, 240#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500# | |||

| L170 | 164*62*15 | ||||

Silicon Carbide Abrasive

The silicon carbide abrasive is used for rough grinding, medium grinding, fine grinding and polishing on the surface of ceramic tiles. It is the grinding and polishing material with the longest application history and the most mature application technology in the field of hard and brittle material polishing. It still occupies a large market share and has a huge amount of use.

According to the different bonding agents, it can be divided into magnesium oxide bond silicon carbide abrasive and resin bond silicon carbide abrasive.

Magnesium Oxide Bond Silicon Carbide Abrasive

Magnesium oxide bond silicon carbide abrasive (or called magnesite abrasive) is mainly used for grinding polished tiles and polished crystal tiles. It is suitable for automatic polishing line machinery. The products developed by Dymend have the characteristics of high grinding efficiency, good brick surface uniformity and good polishing effect.

| Specifications of Magnesium Oxide Bond Silicon Carbide Abrasive | |||||

|---|---|---|---|---|---|

| Description | Length Type(mm) | Dimension(mm) Length*Width*Height |

Grit | Application | Note |

| Magnesium Oxide Bond Silicon Carbide Abrasive | L90 | 132*58*12 | 24#, 36#, 46#, 60#, 80#, 100#, 120#, 150#, 180#, 220#, 240#, 280#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500#, 1800#, 2500# | Rough, Medium and Fine Grinding | Special Specifications Can Be Customized |

| L140 | 132*58*15 | ||||

| L170 | 164*62*12 | ||||

Resin-Bond Silicon Carbide Abrasive for Mat Ceramic Tiles

The resin-bond silicon carbide abrasive can be installed on ordinary polishing equipment to perform matte treatment on the surface of ceramic tiles to achieve a smooth surface, uniform color and ideal gloss. The tiles’ gloss after polishing can achieve the range of 4° to 9°.

| Specifications of Resin-Bond Silicon Carbide Abrasive | |||||

|---|---|---|---|---|---|

| Description | Length Type(mm) | Dimension(mm) Length*Width*Height |

Grit | Application | Note |

| Resin-Bond Silicon Carbide Abrasive | L140 | 132*58/45*38 | 36#, 46#, 60#, 70#, 120#, 150#, 180#, 240#, 320#, 400#, 500#, 600#, 800#, 1200#, 1500# | Mat Ceramic Tiles | Special Specifications Can Be Customized |

| L170 | 164*62/48*48 | ||||

Grinding Brush

By installing the grinding brush on the ordinary polishing machine, the flat, concave, convex and sheepskin surfaces of antique tiles and porcelain tiles are subjected to profiling and matte treatment, which has long service life and good processing effect and can make the brick surface appear silky satin. Faceted and antique effects, the luminosity can be between 6° and 30°.

| Specifications of Grinding Brush | ||||

|---|---|---|---|---|

| Description | Length Type(mm) | Grit | Application | Note |

| Grinding Brush | L140 | 36#, 46#, 60#, 70#, 120#, 150#, 180#, 240#, 320#, 400#, 500#, 600#, 800#, 1200#, 1500# | For Glazed Porcelain Tiles and Granito Tiles | Special Specifications Can Be Customized |

| L170 | ||||

Glaze Tile Polishing Tools

The glaze layers on glazed tiles can be jet-printed, so the colors and patterns are rich, and the anti-fouling ability is also strong. Compared with polished tiles, the surface of glazed tiles is more delicate, and the production process is also more complicated, which causes the abrasive tools used to be different in surface treatment.

Because the glaze surface is relatively hard, brittle and not wear-resistant, tile manufacturers usually use resin-bonded abrasive tools to polish glazed tiles, mainly including glaze polishing abrasives and glaze polishing wheels.

Glaze Polishing Abrasive

The glaze polishing abrasive can be installed on the ordinary polishing machine to carry out the full-polishing or semi-polishing processing of the brick surface of antique tiles, imitation stone tiles, polished crystal tiles, glazed tiles, etc. The glaze polishing abrasives developed by Dymend have good profiling, and grinding effect, it has the characteristics of strong cutting force, high polishing gloss, no wear marks and long service life.

| Specifications of Glaze Polishing Abrasive | ||||||

|---|---|---|---|---|---|---|

| Description | Length Type(mm) | Dimension | Segment Shape | Grit | Application | Note |

| Glaze Polishing Abrasive | L100 | 95*58 | Square Shape/Linear Shape/Curved Shape | 150#, 180#, 240#, 320#, 400#, 500#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, 3000#, 5000#, 8000# | For Glaze Tiles | Special Specifications Can Be Customized |

| L140 | 129*60 | Square Shape/Bevel Shape/Linear Shape/Curved Shape | ||||

| L170 | 164*62 | Square Shape/Bevel Shape | ||||

Glaze Polishing Wheel

Glaze polishing wheels are used on special glaze polishing machines equipped with satellite spindles to make flexible full-polishing and semi-polishing on the surfaces of rustic tiles, stone-like porcelain tiles, crystal-effect polished porcelain tiles and glazed tiles. The glazed polishing wheels produced by Dymend have the advantages of low cost, high grinding efficiency, high polishing gloss and no wear marks.

| Specifications of Glaze Polishing Wheel | ||||

|---|---|---|---|---|

| Description | Length Type(mm) | Grit | Application | Note |

| Glaze Polishing Wheel | Φ100 | 50#, 80#, 100#, 120#, 150#, 240#, 300#, 320#, 400#, 500#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, 3000#, 5000#, 8000# | For Glaze Tiles | Special Specifications Can Be Customized |

| Φ125 | ||||

Diamond Squaring Wheel

The diamond squaring wheel is used to grind the four edges of the tiles to make the edges even. The diamond squaring wheels manufactured by Dymend are very competitive and can be customized in various installation sizes according to customers’ requirements, which are widely used in the production lines of ceramic tile manufacturers.

- Good sharpness, long service life and low noise.

- It is very good to ensure the verticality and size requirements while processing, and no edge or corner chipping;

- The production process is strictly controlled and the product quality is stable;

- Choose a reasonable formula and particle size for different specifications of tiles.

Diamond squaring wheels can be divided into peripheral squaring wheels and disc squaring wheels according to the grinding method. According to the bonding agent, the disc squaring wheels can be divided into metal-bonded diamond disc squaring wheels and resin-bonded diamond disc squaring wheels, according to the processing water environment, it can be also divided into dry grinding wheel and wet grinding wheel.

Metal-Bond Diamond Peripheral Squaring Wheel

The metal-bond diamond peripheral squaring wheel is used for the edging of glazed floor tiles and the rough edging of polished tiles. The main function is to pursue the efficiency of squaring, so the flatness of the tile edge is relatively low.

| Specifications of Metal-Bond Diamond Peripheral Squaring Wheel | ||||||

|---|---|---|---|---|---|---|

| Description | Outer Diameter(mm) | Inner Diameter of Metal Body(mm) | Installation Screw Hole Size(mm) | Segment Size(mm) | Application | Note |

| Metal-Bond Diamond Peripheral Squaring Wheel | Φ310 | Φ150 | 4M12/6Φ13 | 9*10 | For Glaze Floor Tiles and Polished Porcelain Tiles | Special Specifications Can Be Customized |

| Φ150 | 6Φ13 | |||||

Metal-Bond Diamond Disc Squaring Wheel

The metal-bond diamond disc wheel is the most commonly used ceramic tile edging wheel, which can be applied to the edging of all ceramic tile styles. According to the segment structure, it is classified into segmented squaring wheel, segmented-continuous rim squaring wheel and continuous-rim squaring wheel.

However, tile manufacturers are more inclined to classify diamond squaring wheels according to the water environment in which the tiles are processed.

Metal-Bond Diamond Disc Squaring Wheel for Dry Grinding

Tiles with high water absorption have poor scratch resistance, but they are very decorative, so they are mostly used for building wall decoration. In the production process, dry grinding wheels are generally selected for edging, because the water grinding environment can easily lead to problems such as dyeing and edge chipping.

The metal-bond diamond disc squaring wheels for day grinding produced by Dymend have good generality, good sharpness, high cost-performance and high processing efficiency. The producing volume of one production line can be stabilized at 8500-14000 square meters per day, and it is suitable for ceramic inner wall tiles with a water absorption rate of 3-20%, antique floor tiles with a water absorption rate of 0.5-6%.

Metal-Bond Diamond Disc Squaring Wheel for Wet Grinding

The edges of the ceramic tiles with low water absorption such as polished tiles, glazed tiles, diamond glazed tiles, etc. are usually processed in the water environment so that the processing and cooling effect is good and the production capacity is high.

Dymend strictly controls the production quality of wet grinding wheels, and the chipping angle is controlled within 0.2% during use. The product has strong versatility, good sharpness and high processing efficiency. Under the standard equipment configuration, the output of ceramic tiles in one production line is stable at 15500-30000 square meters per day.

| Specifications of Metal-Bond Diamond Disc Squaring Wheel | ||||

|---|---|---|---|---|

| Description | Outer Diameter(mm) | Segment Size(mm) | Application | Note |

| Segmented Squaring Wheel | Φ150 | 8*12 8*12 10*14 |

Polished Tiles Polishing Glazed Tiles Diamond Glazed Tiles Inner Wall Tiles |

Special Specifications Can Be Customized |

| Φ200 | ||||

| Φ250 | ||||

| Φ300 | ||||

| Segment Continuous-Rim Squaring Wheel | Φ150 | 11*12 | ||

| Φ200 | 10*10 | |||

| Φ250 | 8*12 10*14 |

|||

| Φ300 | 10*14 | |||

| Continuous Rim Squaring Wheel | Φ150 | 8*12 10*14 |

||

| Φ200 | ||||

| Φ250 | ||||

| Φ300 | 12*14 | |||

Resin-Bond Diamond Disc Squaring Wheel

The resin-bond diamond disc squaring wheels are suitable for fine edge squaring of ceramic tiles, with high dimensional accuracy, and the edging effect is straight and smooth. According to the structure of the grinding segments, it can be divided into continual rim squaring wheel and segmented squaring wheel.

Similar to the metal-bond diamond disc grinding wheels, manufacturers are accustomed to classifying resin-bond diamond disc squaring wheels according to the water using condition.

Resin-Bond Diamond Disc Squaring Wheel for Dry Grinding

The resin-bond diamond dry-squaring wheel can also be called the resin-bond diamond dry chamfering rough grinding wheel or resin-bond diamond dry grinding trimming wheel, it has high sharpness, long life, good grinding adaptability, high thermal stability, can still show good grinding performance under extremely high temperatures, and large grinding volume, the maximum grinding amount on one side reaches 0.6mm.

Resin-Bond Diamond Disc Squaring Wheel for Wet Grinding

The resin-bond diamond disc wet-squaring wheel developed and manufactured by Dymend has high cost-performance, good sharpness and good grinding effect. In the case of high linear speed processing, there will be no chipping, and the maximum grinding amount on one side can reach 0.5mm.

| Specifications of Resin-Bond Diamond Disc Squaring Wheel | |||||

|---|---|---|---|---|---|

| Description | Outer Diameter(mm) | Segment Size(mm) | Grit | Application | Note |

| Resin-Boind Diamond Squaring Wheel with Continuous Rim | Φ200 | 40*12 | 80#, 100#, 120#, 140#, 170#, 200#, 230#, 270# | Fine Squaring for Ceramic Tiles | Special Specifications Can Be Customized |

| Φ200 | 25*12 | ||||

| Φ250 | 40*12 | ||||

| Φ250 | 25*12 | ||||

| Resin-Boind Diamond Squaring Wheel with Flume Between Working Layer | Φ200 | 40*12 | |||

| Φ250 | 40*12 | ||||

| Φ250 | 25*12 | ||||

Diamond Chamfering Wheel

The diamond chamfering wheel is the abrasive tool for ceramic tile chamfering after squaring the edges, which is beneficial to the safety of ceramic tiles during storage, transportation, installation and construction.

According to the segment structure, it can be divided into the segmented chamfering wheel and the continuous rim chamfering wheel. The segmented chamfering wheel has a strong grinding capacity and can be used for chamfering large corners, and it is generally used for chamfering before surface polishing. The continuous rim chamfering wheel is normally used for chamfering after polishing.

According to the different bond materials, the diamond chamfering wheel is classified into the metal-bond diamond chamfering wheel, the resin-bond diamond chamfering wheel, and the resin-bond silicon carbide chamfering wheel.

Metal-Bond Diamond Chamfering Wheel

The metal bond has a good ability to hold the diamond, and then the advanced sintering technology is used to produce the metal-bond diamond chamfering wheel with reliable quality, Dymend’s products have the characteristics of high chamfering efficiency and good effect.

| Specifications of Metal-Bond Diamond Chamfering Wheel | ||||

|---|---|---|---|---|

| Description | Outer Diameter(mm) | Segment Size(mm) | Application | Note |

| Metal-Bond Diamond Chamfering Wheel | Φ120 | 9*9 9*14 |

Chamfering for Ceramic Tiles | Special Specifications Can Be Customized |

| Φ125 | ||||

| Φ130 | ||||

| Φ135 | ||||

| Φ150 | ||||

Resin-Bond Diamond Chamfering Wheel

The resin-bond diamond chamfering wheel is suitable for fine chamfering of ceramic tiles. Dymend’s products have high sharpness, straight and smooth chamfering surfaces, and long continuous service life.

| Specifications of Resin-Bond Diamond Chamfering Wheel | ||||

|---|---|---|---|---|

| Description | Size(Outer Diameter – Width * Thickness)(mm) | Segment Size(mm) | Application | Note |

| Resin-Bond Diamond Chamfering Wheel(Aluminum Body) | Φ100 – 40/10 * (15 ~ 20) | 230#, 270#, 320#, 400#, 600#, 800# | Chamfering for Ceramic Tiles | Special Specifications Can Be Customized |

| Φ125 – 25 * (15 ~ 20) | ||||

| Φ130 – 40/35/30/25 * (10 ~ 20) | ||||

| Φ150 – 40/35/30/25/20/15 * (10 ~ 20) | ||||

| Resin-Bond Diamond Y3 Chamfering Wheel(Rotation Left/Right) | Φ130 – 40 * (10 ~ 20) | 100#, 120#, 150#, 170# | ||

| Resin-Bond Diamond Y6 Chamfering Wheel(Rotation Left/Right) | Φ100 – 34 * 10.5 | 100#, 120#, 150#, 170# | ||

Resin-Bond Silicon Carbide Chamfering Wheel

The resin-bond silicon carbide chamfering wheel is used for the fine chamfering of ceramic tiles. It has the characteristics of high sharpness, straight and smoothes the chamfered surface and long continuous service life.

| Specifications of Resin-Bond Silicon Carbide Chamfering Wheel | ||||

|---|---|---|---|---|

| Description | Size(Outer Diameter – Width * Thickness)(mm) | Segment Size(mm) | Application | Note |

| Resin-Bond Silicon Carbide Y3 Chamfering Wheel(Aluminum Body) | Φ125 – 25 * (15 ~ 20) | 150#, 180#, 240#, 320# | Chamfering for Ceramic Tiles | Special Specifications Can Be Customized |

| Φ130 – 40 * 18 | ||||

| Resin-Bond Silicon Carbide Y3 Chamfering Wheel(Rotation Left/Right) | Φ130 – 40 * (12 ~ 18) | 150#, 180#, 240#, 320# | ||

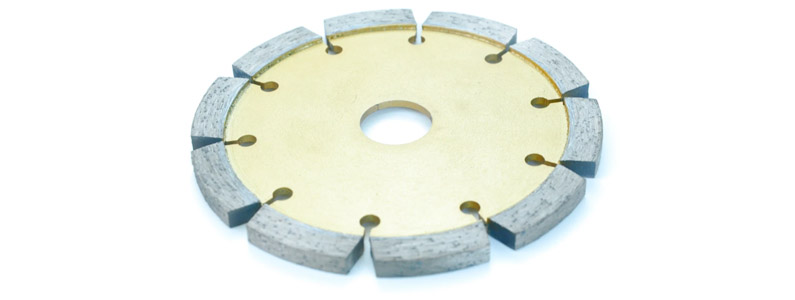

Diamond Cutting Disc

Diamond saw blades are more and more widely used in ceramic tile processing. They can be used for mosaic cutting, edge trimming, grooving, etc. They are suitable for automatic continuous cutting machines, manual cutting machines and other equipment. There are four working models including manual single-blade full cutting, automatic single-blade full cutting, automatic two-blade full cutting, pre-cutting, chamfering and full cutting. Dymend’s diamond circular cutting blade has the characteristics of low tiles edge-breaking, high working speed, long service life, and can realize the fine and precise ceramic cutting effect.

Whole Sintered Diamond Cutting Disc

The whole sintered diamond cutting disc is used to make full cutting, half-cutting and grooving on polished porcelain tiles, wearable ceramic tiles, rustic tiles, glazed floor tiles, and glazed wall tiles. The circular disc can be used for multi-blade cutting and single-blade cutting. It is suitable for single-head or two-head automatic continuous cutting machines and manual cutting machines. The whole sintered diamond cutting disc manufactured by Dymend has the characteristics of good sharpness, smooth and flat cutting slots and no chipping.

| Specifications of Whole Sintered Diamond Cutting Disc | |||||||

|---|---|---|---|---|---|---|---|

| Outer Diameter | Segment Thickness(mm) | Segment Height(mm) | Arbor(mm) | Grit | Application | Note | |

| Inches | Metric(mm) | ||||||

| 4 | 105 | 1.8 | 8 | 20 | D64 D76 D91 D107 D126 D151 D181 D213 D252 D301 D427 |

Make Full Cutting, Half-cutting and Grooving on Ceramic Tiles | Special Specifications Can Be Customized |

| 4⅓ | 110 | 1.8 | 7/10 | 20 | |||

| 4.5 | 114 | 1.8 | 7/10 | 20 | |||

| 5 | 125 | 1.8/2.0 | 7/10 | 20 | |||

| 5¼ | 130 | 2.0/2.2 | 10 | 20 | |||

| 6 | 150 | 2.0/2.2 | 7/10 | 20/22.23/50/60 | |||

| 7 | 180 | 2.0/2.2 | 7/10 | 20/22.23/50/60 | |||

| 8 | 200 | 2.0/2.2 | 7/10 | 22.23/50/60 | |||

| 10 | 250 | 2.0/2.2/2.4 | 9/10 | 60 | |||

| 12 | 300 | 1.6/1.8/2.0/2.2/2.4/2.6/2.8/3.0 | 9/10 | 60 | |||

| 14 | 350 | 2.0/2.2/2.4/2.6/2.8 | 8/10 | 50/60 | |||

| 16 | 400 | 2.2/2.4 | 10 | 75 | |||

Welded Diamond Cutting Disc

The welded diamond cutting disc is used for cutting polished porcelain tiles, rustic tiles, glazed floor tiles, wear-resistant tiles, etc. It has the characteristics of sharp cutting, straight and smooth slits, no collapse, and long service life. It can be used for multi-blade cutting and single-blade cutting, suitable for single-head or double-head automatic continuous cutting machines and manual cutting machines.

| Specifications of Whole Sintered Diamond Cutting Disc | |||||||

|---|---|---|---|---|---|---|---|

| Outer Diameter | Segment Thickness(mm) | Segment Height(mm) | Arbor(mm) | Grit | Application | Note | |

| Inches | Metric(mm) | ||||||

| 7 | 180 | 1.8/2.0 | 1.8/2.0 | 60 | D107 D126 D151 D181 D213 D252 D301 D427 |

Make full cutting, half-cutting and grooving On Ceramic Tiles | Special Specifications Can Be Customized |

| 8 | 200 | 1.8/2.0 | 1.8/2.0 | 60 | |||

| 10 | 250 | 1.8/2.0/2.2/2.4 | 1.8/2.0/2.2/2.4 | 60 | |||

| 12 | 300 | 1.2/1.4/1.6/1.8/2.0/2.2/2.4 | 1.2/1.4/1.6/1.8/2.0/2.2/2.4 | 60 | |||

| 14 | 350 | 2.8/3.0/3.2 | 2.8/3.0/3.2 | 50/60 | |||

| 16 | 400 | 2.8/3.0/3.2 | 2.8/3.0/3.2 | 50/60 | |||

Diamond Grooving Disc

The diamond grooving disc is used for grooving polished porcelain tiles, rustic tiles, glazed floor tiles, glazed wall tiles, wearable resistant tiles, etc. It has the characteristics of good sharpness, straight grooving, no chipping, long working life and flat cutting bottom. The diamond grooving blade can be used for single-blade and multi-blade cutting and is suitable for single-head continuous cutting machines and manual cutting machines.

| Specifications of Diamond Grooving Disc | |||||||

|---|---|---|---|---|---|---|---|

| Outer Diameter | Segment Thickness(mm) | Segment Height(mm) | Arbor(mm) | Grit | Application | Note | |

| Inches | Metric(mm) | ||||||

| 4.5 | 115 | 2.8/4.0/5.0 | 7 | 20 | D107 D126 D151 D181 |

Make full cutting, half-cutting and grooving On Ceramic Tiles | Special Specifications Can Be Customized |

| 6 | 150 | 3.0/4.0/5.0/6.0/10/15/20/30/40 | 7 | 30/32/50/60 | |||

| 7 | 180 | 3.8/5.0/10.0 | 7 | 30/32/50/60 | |||

| 8 | 200 | 4.0/5.0/6.0/10 | 7 | 30/32/50/60 | |||

| 10 | 250 | 3.0/3.8/4.0/5.0/6.0/8.0/10/15/20 | 7 | 50/60 | |||

| 12 | 300 | 3/3.8/4/4.8/5.0/6.0/8.0/10 | 7 | 50/60 | |||

Resin Diamond Grinding Wheel Slot

The resin diamond grinding wheel slot is applied to groove and slot the surface of all ceramic tiles, such as ceramic polished tiles, antique tiles, glazed wall and floor tiles, etc. It has good sharpness, no collapse, constantly brick, and the bottom surface of the slot is smooth. The resin diamond grinding wheel slot can also be combined with fine-grained diamond for fine grinding and polishing.

| Specifications of Resin Diamond Grinding Wheel Slot | ||||||

|---|---|---|---|---|---|---|

| Outer Diameter(mm) | Thickness(mm) | Width(mm) | Arbor(mm) | Grit | Application | Note |

| 150 | 6 | 15 | 32 | 80#, 140# | Make Slot On the Surface of Ceramic Tiles | Special Specifications Can Be Customized |

| 10 | ||||||

| 15 | ||||||

| 20 | ||||||

| 200 | 5 | 20 | 60 | 60#, 80#, 140#, 320#, 500#, 800#, 1200# | ||

| 8 | ||||||

| 10 | ||||||

| 15 | ||||||

| 19 | ||||||

| 20 | ||||||

| 25 | ||||||

| 300 | 5 | 10 | 60 | 80#, 140#, 320#, 500#, 800#, 1200# | ||

| 10 | ||||||

| 15 | ||||||

| 20 | ||||||

| 25 | ||||||

| 30 | ||||||

Diamond Chamfering Disc

The diamond chamfering disc can be used for chamfering of polished porcelain tiles, rustic tiles, glazed floor and wall tiles, wearable ceramic tiles, etc. It has the characteristics of good sharpness, smooth chamfering, no chipping, and a long working lifetime. It can be used by single-blade or multi-blade and is suitable for the three-heads continuous cutting machines or manual cutting machines. The operation process of the three-head cutting machine is the first head for pre-cutting, the second head for chamfering, and the third head for full cutting.

| Specifications of Resin Diamond Grinding Wheel Slot | |||||||

|---|---|---|---|---|---|---|---|

| Outer Diameter(mm) | Segment Thickness(mm) | Segment Height(mm) | Arbor(mm) | Grit | Application | Note | |

| Inches | Metric(mm) | ||||||

| 6 | 150 | 4.0/5.0/6.0 | 7 | 30/32 | D91 D107 D126 D151 D181 |

Make Slot On the Surface of Ceramic Tiles | Special Specifications Can Be Customized |

| 8 | 200 | 4.0/5.0/6.0 | 7 | 30/32 | |||

| 10 | 250 | 4.0/5.0/6.0 | 7 | 50/60 | |||

| 12 | 300 | 4.0/5.0/6.0/10.0 | 7 | 50/60 | |||