In the stone industry, whether it is natural stone or artificial stone, it needs to be cut into slabs from blocks, polished on the surface of the slabs and chamfered on the slab edges. Therefore, Dymend provides a complete set of diamond tool solutions.

Our products have the following characteristics:

- Good sharpness and long service life.

- Good polishing effect, high definition, high gloss.

- The cutting, grinding and polishing rate is high, and the stone waste is reduced.

Diamond Segment

Diamond segments are the most commonly used tools in the processing of natural stone. For example, in the mining stage, a circular saw is used for cutting, in the stone factories processing stage, cutting the stone blocks into slabs by using a single-blade saw or multi-blades saw, all need to use the diamond segments.

Dymend provides diamond segments in a variety of sizes and shapes, including sector shape, stepped type, grooved type, etc., and we can provide customized services.

| Specifications of Diamond Segment | ||||

|---|---|---|---|---|

| Application | Segment Length(mm) | Segment Thickness | Segment Height(mm) | Note |

| Quarrying and Cutting Marble and Granite Blocks | 23 24 |

7.4/6.6 | 14/13 15.5/15 |

Product Customization and Brand OEM Are Available |

| 8.4/7.6 | ||||

| 9.4/8.6 | ||||

| 10.4/9.6 | ||||

Diamond Cylindrical Wheel

After the stone is cut into slabs from blocks, the surface is relatively rough and the thickness is different, which usually needs to be calibrated. The commonly used thickness calibrating tool for artificial quartz and granite is the diamond cylindrical wheel.

| Specifications of Diamond Cylindrical Wheel | ||||

|---|---|---|---|---|

| Diameter(mm) | Grit | Segment Type | Application | Note |

| Φ180 | 24# – 120# | Blade Type | Rough Grinding and Calibrating of Artificial Quartz and Granite | Product Customization and Brand OEM Are Available |

| Φ200 | Segment Type | |||

| Φ230 | Continuous Type | |||

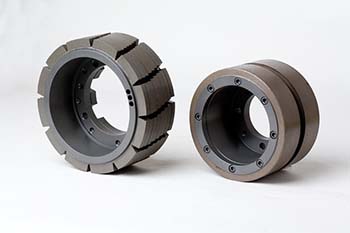

Diamond Calibrating Roller

The diamond calibrating roller can be used for rough grinding and thickness calibrating of artificial quartz slabs, with better service life and sharpness.

Dymend can customize diamond calibrating roller in a variety of lengths and diamond segment arrangements.

| Specifications of Diamond Calibrating Roller | ||||

|---|---|---|---|---|

| Diameter(mm) | Grit | Segment Shape | Application | Note |

| Φ240 | 24# – 120# | Helix | Rough Grinding and Calibrating of Artificial Quartz | Product Customization and Brand OEM Are Available |

Diamond Grinding Strip

The diamond grinding strips can be used for rough grinding and thickness calibrating of artificial quartz stone surfaces.

Dymend can provide the finished diamond grinding strips or diamond segments for customers to weld.

| Specifications of Diamond Grinding Strip | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Length(mm) | Segment Height(mm) | Grit | Application | Note |

| 155*20*20 | 22/24/40 | 15/20 | 24# – 120# | Rough Grinding and Calibrating of Artificial Quartz | Product Customization and Brand OEM Are Available |

Diamond Grinding Plate

The diamond grinding plate is also one of the common tools for thickness calibrating and grinding of artificial quartz stone and granite.

| Specifications of Diamond Grinding Plate | ||||

|---|---|---|---|---|

| Diameter(mm) | Bore(mm) | Grit | Application | Note |

| 100-150 4″ – 6″ |

16/20/22.23 | 24# – 180# | Rough Grinding, Calibrating or Polishing of Artificial Quartz and Granite | Product Customization and Brand OEM Are Available |

Diamond Fickert

After the stone slab is calibrated, it needs to be polished on the surface, so that the original texture of the stone can be displayed and the gloss can be improved. Diamond fickert can be used to replace the old process of silicon carbide abrasives to polish the surface of the slab.

At the beginning of grinding and polishing, the particle size of the surface of the stone slab is relatively large, and the loss of abrasive tools is large correspondingly. Therefore, metal-bond diamond fickert is used for low-grit grinding and polishing, because metal-bond diamond fickert has a stronger clamping ability to diamond and has a longer life.

In the subsequent processing, in order to improve the gloss of the slab surface, resin-bond diamond fickert is used for high-grit grinding and polishing.

| Specifications of Diamond Fickert | |||||

|---|---|---|---|---|---|

| Bond | Length(mm) | Segment Size(mm) | Grit | Application | Note |

| Metal Bond | L140 | 133*56*17 | 24# – 240# | Rough and Fine Grinding | Product Customization and Brand OEM Are Available |

| L170 | 164*56*17 | 24# – 240# | |||

| Frankfurt | 100*106/80 | 24# – 240# | |||

| Resin Bond | L140 | 140*60*60 | 240# – 3000# | Fine and Precision Grinding | |

| L170 | 170*70*60 | 180# – 5000# | |||

Silicon Carbide Abrasive

It is suitable for grinding all kinds of marble, granite and artificial stone slabs surfaces.

Dymend can provide various shapes of silicon carbide abrasive according to requirements.

| Specifications of Silicon Carbide Abrasive | ||||

|---|---|---|---|---|

| Type | Dimension(mm) | Grit | Application | Note |

| Trapezoid Type | 128*80*52 | 36# – 2500# | Polishing of Granite & Quartz Slabs | Product Customization and Brand OEM Are Available |

| Trapezoid Type | 162*80*52 | |||

| Frankfurt | 104*104/84*45 | 36# – 1200# | Polishing of Marble & Artificial Granite Slabs | |

Grinding Brush

The grinding brush has a diamond powder on the bristles, which is used for the semi-gloss treatment of all kinds of marble, granite and artificial stone slabs.

Dymend provides the trapezoid brush, frankfurt brush and plate-shaped brush.

| Specifications of Grinding Brush | ||||

|---|---|---|---|---|

| Type | Length(mm) | Grit | Application | Note |

| Trapezoid Type | 140 | 36# – 1500# | Granite, Marble and Quartz | Product Customization and Brand OEM Are Available |

| Trapezoid Type | 170 | |||

| Frankfurt | 104 | |||

| Plate-shaped Type | Φ150 | |||

Diamond Grinding Wheel for Profiling

After the surfaces of the stone slabs are polished, the edges of the slabs need to be squared and chamfered. The diamond grinding wheel is used for edging processing of various natural and artificial stone special-shaped corners.

Dymend can provide diamond grinding wheels of various sizes according to customer requirements, and supports both electroplating and sintering processes, suitable for all squaring machines for special shapes.

*Can be customized according to customer drawings.