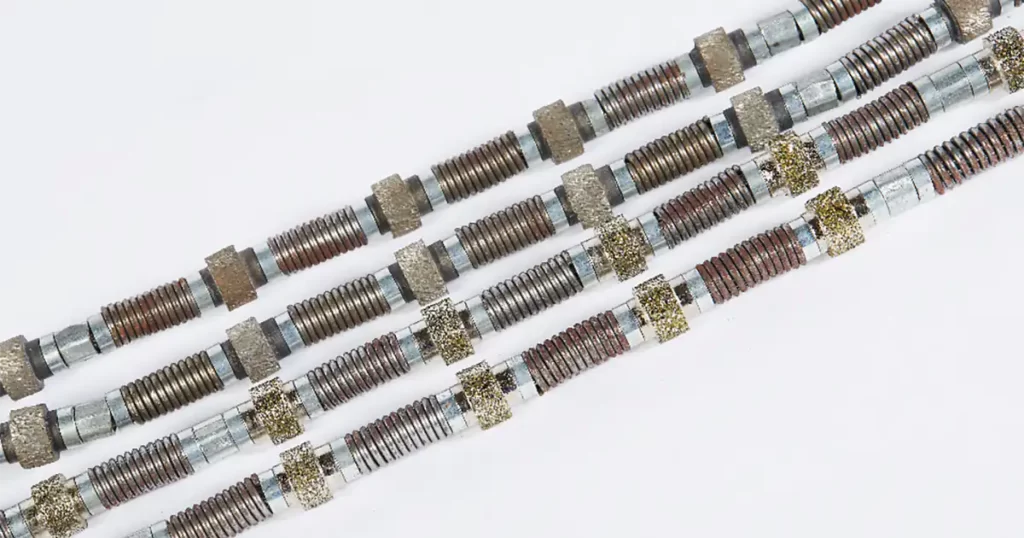

Dymend Tools listed the common diamond wire saws on the market, which have different diameters and the number of diamond wire beads. This leads to a new question: how to select the suitable diameter and quantity of diamond wire beads among the various specifications of diamond wire saws?

Generally, the number of diamond wire beads installed per meter of diamond wire saw is related to the diamond wire structure, diamond wire bead type and sawing application. The softer the cut stone, the fewer diamond wire beads are installed per meter.

Select the Diameter of Diamond Wire Beads

The diameter of the diamond bead should be selected according to its application.

Generally, the diameter of the diamond wire saw used in stone mining is more than 10mm. When mining and cutting marble, electroplated or sintered diamond beads with a diameter of 10mm shall be selected. When mining granite, sintered diamond beads with a diameter of 11 mm are selected.

When cutting stone slabs with diamond wire saw, in order to reduce the loss of stone caused by too large saw gap, should try to select diamond beads with small diameters, such as 7~9mm diameter diamond beads. When cutting special-shaped stone products, diamond beads with a diameter of 8~10mm are often used.

When using the diamond multi-wire saw to cut granite slabs, in order to have more advantages over the sand saw and reduce the loss of stone, the diameter of the diamond beads used by the diamond multi-wire saw is 7.2-8.2mm, and sometimes even the smaller diameter diamond bead is used, such as 6mm. Diamond wire saws with diamond bead diameter less than or equal to 6mm are mostly used in small desktop wire saw machines for the mosaic of stone products and the cutting and processing of special-shaped plate products.

Diamond beads with a diameter of 10-12mm are generally used for cutting concrete or reinforced concrete containing various aggregates.

Select the Quantity of Diamond Wire Beads

Different types of stone and concrete have different physical cutting properties. Dymend lists the following tables for description.

- Category of stone cutting performance

| Stone Category | Cutting Performance |

|---|---|

| Level 1 | Soft material with large abrasion position and low abrasion resistance |

| Level 2 | Medium wear consumption and wear resistance |

| Level 3 | Medium strength stone |

| Level 4 | Materials with medium hardness, low abrasion resistance and high wear resistance |

| Level 5 | Hard material with low abrasion resistance and high wear resistance |

- Category of concrete cutting performance

| Concrete Category | Cutting Performance |

|---|---|

| Containing granite aggregate | High strength |

| Containing limestone aggregate | Medium strength |

| Containing limestone aggregate | Low strength |

| Reinforced concrete | High strength |

| Plain concrete with masonry structure | Low strength |

When mining and cutting soft stones such as marble, limestone and travertine, the spring type diamond wire saw is more suitable in terms of reducing cutting costs. From the perspective of safety, it is appropriate to use sintered diamond beads or electroplated diamond beads, and diamond wire saw with plastic injection structure. When selecting electroplated diamond beads or sintered diamond beads for marble cutting, at least 25 diamond beads per meter of length shall be installed. Generally, 28, 30 and 32 diamond beads can be installed per meter of diamond wire saw. When cutting hard marble such as serpentine, a diamond wire saw with 35~38 diamond beads per meter can be selected.

When mining and cutting granite and other hard stones, a plastic injection diamond wire saw with sintered diamond beads shall be used. At least 38~40 diamond beads shall be installed on the diamond wire saw per meter of length. When cutting some superhard granite, a diamond wire saw with 42 diamond beads per meter can be selected.

Conclusion

According to the above discussion, the diamond wire saw needs to be selected according to the cutting objects and the applications in the selection of the diameter and quantity of diamond wire beads. We summarized the rules and make the following table, combined with the previous research on the selection of the length of diamond wire saw, which can help users quickly match the suitable diamond wire saw.

| Types of Diamond Wire Saw | Diameter(mm) | Number of Diamond Beads/m-1 | Application |

|---|---|---|---|

| Electroplated Diamond Beads with Spring/Plastic Injection | 8.6-11.5 | 25-38 | Mining Marble(Spring Type), Shaping or Special-shape Cutting(Plastic Injection Type) |

| Sintered Diamond Beads with Plastic Injection | 8.6-11.5 | 35-42 | Mining Granite or Hard Marble, Shaping or Special-shape Cutting |

| Electroplated/Sintered Diamond Beads with Plastic Injection | 7.2-8.2 | 31-35 | Cutting Marble Slab or Special-shape |

| Sintered Diamond Beads with Plastic Injection | 7.2-8.2 | 35-40 | Cutting Granite Slab or Special-shape |

| Electroplated Diamond Beads with Plastic Injection | 6-8.2 | 31-35 | Cutting Marble Slab with Diamond Multi-wire Saw |

| Sintered Diamond Beads with Plastic Injection | 6-8.2 | 35-40 | Cutting Marble/Granite Slab with Diamond Multi-wire Saw |

| Electroplated Diamond Beads with Spring Frame and Plastic Injection | 6-12 | 32-39 | Cutting Plain Concrete Components and Other Special Purposes |

| Sintered Diamond Beads with Spring Frame and Plastic Injection | 6-12 | 32-39 | Cutting Reinforced Concrete Components and Other Special Purposes |

| Electroplated/Sintered Diamond Beads with Rubber Injection | 6-11.5 | 31-40 | Cutting Stone or Concrete at Low Temperature |