- What is Diamond Wire Saw

- Development History of Diamond Wire Saw

- Composition and Manufacture of Diamond Wire Saw

- Application of Diamond Wire Saw

- Frequently Asked Questions When Using a Diamond Wire Saw

- How to Use Diamond Wire Saw Correctly

- the Top 5 Diamond Wire Saw Manufacturers

- Development of Diamond Wire Saws in China

- Development Trend of Diamond Wire Saw

- Conclusion

The first diamond wire saw and corresponding equipment appeared in the stone kingdom – Italy, at the Italian VERONA S. Ambrogio Stone Expo(1969-1970), a wire saw with electroplating beads and processing equipment were exhibited for the first time(See our supplementary article for more information on the development history of diamond wire saw). Since then, this potential tool has been rapidly developed in manufacturing methods, processing objects, application scope, processing equipment and other aspects. Sawing speed and processing efficiency have been greatly improved.

With the development of material technology and the demand for material processing, diamond wire saws(or wire saws) are gradually introduced into processing fields other than building materials, such as semiconductor materials, foam, glass, metal, outdoor adventure tools (wood cutting) and so on. Dymend is committed to the research and development of processing tools for building materials, therefore, here we only discuss diamond wire saws for building materials processing, mainly including marble, granite and concrete.

Let’s get started!

What is Diamond Wire Saw

The diamond wire saw is a cutting tool that fixes the diamond on the surface of the wire, by applying pressure to the wire and making continuous mechanical movement, it uses the physical characteristics of the ultra-high hardness of the diamond to grind the material, under the cooling and lubricating action of oil or water, achieve the purpose of cutting materials.

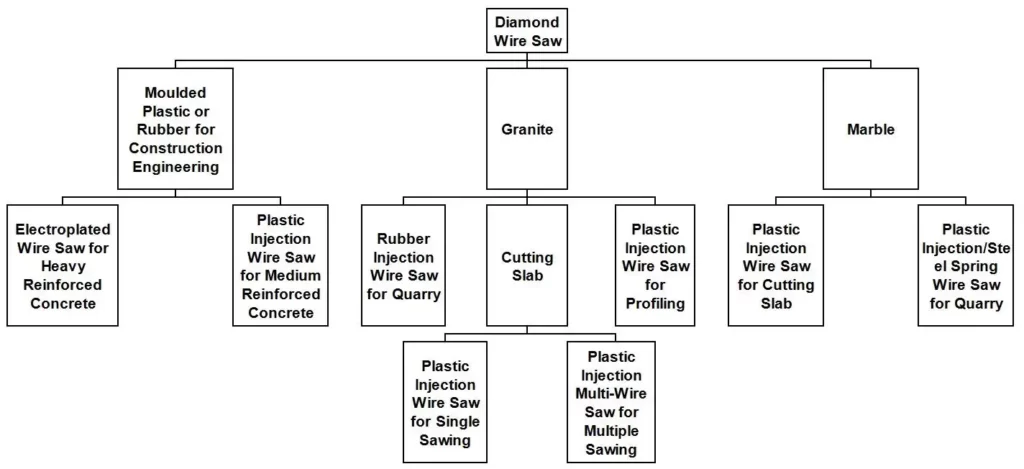

The common diamond wire saws can be divided into 4 types according to the production materials or structures:

- Rubber wire saw

- Plastic wire saw

- Spring wire saw

- Spring plus rubber wire saw

More analysis on the structures of diamond wire saw↗

According to the cutting objects, they can be divided into 8 types:

- Diamond wire saw for granite mining

- Diamond wire saw for granite block shaping

- Diamond wire saw for granite special-shaped processing

- Diamond wire saw for marble mining

- Diamond wire saw for marble block shaping

- Diamond wire saw for marble special-shaped processing

- Diamond multi-wire saw for cutting stone slab

- Diamond wire saw for concrete cutting

See our supplementary articles to learn more about the classification of diamond wire saws↗

At present, there are also mature diamond wire saw machines on the market to work with diamond wire saw cutting. Power components include the hydraulic drive and the latest permanent magnet drive.

Development History of Diamond Wire Saw

Diamond has the highest hardness and elastic modulus in nature, and wire/rope is the most flexible sawing substrate in mechanical sawing. The combination of hardness and flexibility makes diamond wire saw have various unique advantages, which determines its wide application in practical processing.

The diamond bead wire saw was first used for the mining of stone mines. It officially entered the stone mining industry from 1978 to 1979. It has a history of more than 40 years. The diamond bead wire saw technology has entered the stone industry, which is a historic breakthrough in both the mining and processing of stone materials.

After 40 years of research and development, the application of diamond wire saw has made rapid development. ①From the exploitation of marble to the separation and cutting of sandstone, granite and other hard stones/rocks. ②From open-pit mining to the mining of underground narrow veins and underground gold mines in South Africa with explosion risk. ③From the processing of special-shaped stone(marble/granite, etc.) products, to the demolition and repair of buildings and reinforced concrete in construction and road works, and even to the cutting of metal structures and semiconductors.

In China’s stone industry, after about 27 years of development, it has been recognized that the diamond wire saw mining technology not only makes the traditional stone mining work more modern, improves the bad working conditions, but also establishes and consolidates the non-destructive stone mining technology, which is conducive to environmental protection. Today’s bead wire saw has become a mature and universal technology, which has been accepted by stone mines and processing plants in various countries.

As the third-generation product in the development process of diamond tools, diamond wire saws are widely used in various projects after 40 years of research and development and improvement. This is mainly because it has the following advantages:

- The equipment is simple and easy to install. It is not limited by the site and space. It can cut horizontally, vertically and obliquely. The sawing area can reach 200 square meters. It has good processing quality, low stone loss, fast cutting speed, low noise, small vibration, a good working environment and strong adaptability. Diamond wire saw equipment of different specifications and sizes can be selected according to the sawing object and working conditions.

- It can significantly improve the rate of finished stone blocks and protect precious stone resources.

- It can process special-shaped granite and marble products of various shapes, with high added value and significant economic benefits.

- Large-sized stone blocks can be mined, and the finished material specifications can be increased, so as to increase the slab product specifications of advanced stone processing equipment, and improve the cutting efficiency and economic benefits.

The above advantages of diamond wire saw will undoubtedly play a great role in solving the problems of low rate of stone block, shortage of large-sized stone slabs and failure of special-shaped products to meet the requirements in the stone industry. Therefore, the development and promotion of diamond wire saw is a key to the development of the stone industry.

Composition and Manufacture of Diamond Wire Saw

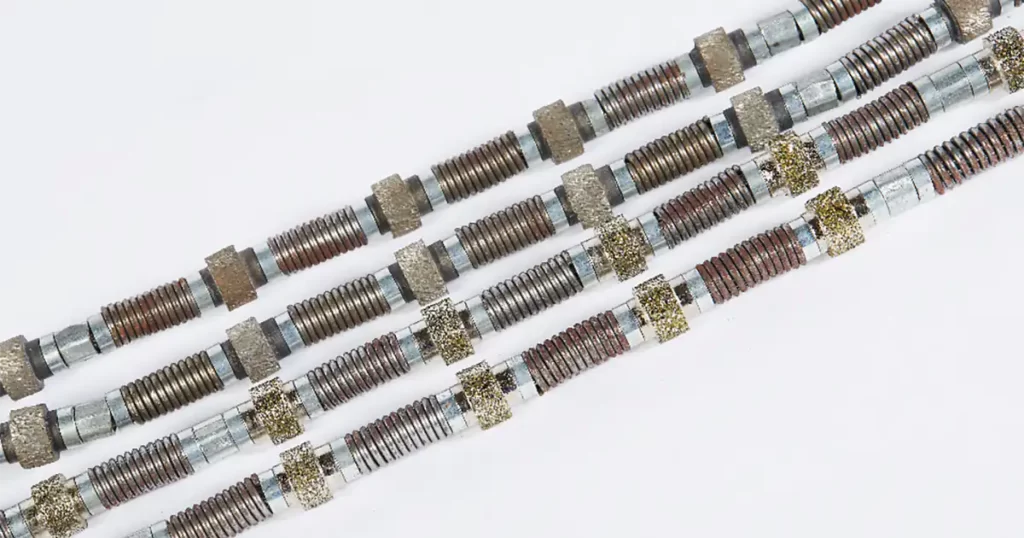

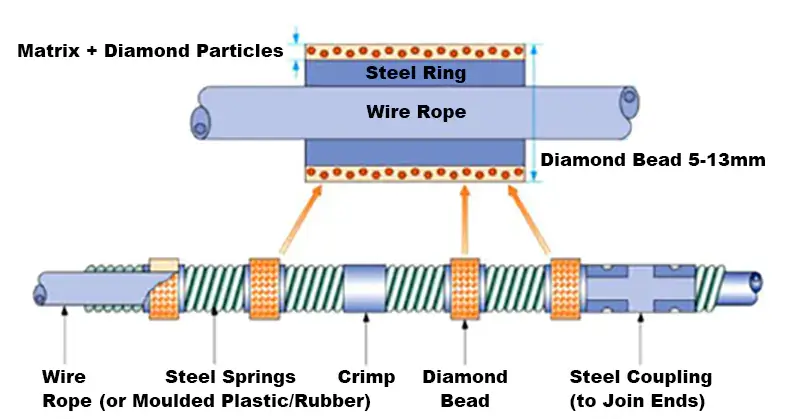

Composition of Diamond Wire Saw

The diamond wire saw is a multi-strand wire rope with a certain number of diamond bead particles on it in proportion. Adjacent beads are separated by a spacer sleeve for support and fixation. The following picture is the structure diagram of the diamond wire saw.

1. Wire Rope

The wire rope is twisted by multiple strands (usually 6-7 strands) of steel wire. It is required to have high breaking strength and low elongation. The length of the rope depends on the user’s needs. The steel ring is sleeved and fixed on the wire rope. The number of steel rings is 32~40 per meter, and a certain distance is kept between the rings.

2. Diamond Bead

Diamond beads are a layer of 40/50# diamond particles and matrix covered on the steel ring, and the inner hole of the steel ring is slightly larger than the diameter of the wire rope. The nominal diameter of diamond beads is generally 5~13mm. With the expansion of the use and processing objects of diamond bead wire saws, the specification, structure and variety of beads are increasingly diversified.

3. Steel Ring

The steel ring is mainly used for the spacing and isolation of diamond beads.

4. Isolation Sleeve

The isolation sleeve is used to separate the diamond beads and make them string along the wire rope in a small range. The commonly used isolation sleeves are steel springs(used for cutting reinforced concrete or marble mining/quarrying), moulded plastic(used for processing in stone factory) and moulded rubber(used for mining/quarrying).

5. Crimp

In general, every five diamond beads on the wire rope form a small cutting unit, that is, a fixing crimp is used to limit the five diamond beads, isolation sleeves like steel springs and steel rings to a range of about 17~18cm.

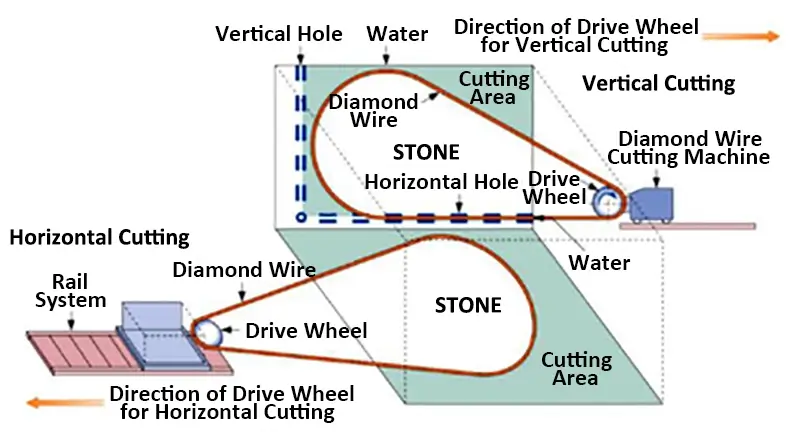

6. Steel Coupling

The diamond wire saw is a closed loop rope when working. Before working, two intersecting holes shall be drilled on both sides of the stone in the vertical or horizontal direction, the diamond wire saw shall be penetrated into the stone, and then the two ends of the wire saw shall be connected with steel coupling/joints/connectors to form a closed rope.

Furthermore, you can also learn more about the accessories required for diamond wire saws↗

How to Manufacture Diamond Wire Saw

Manufacturing Diamond Bead

From the invention of diamond wire saw to the present, the improvement of the diamond bead production process has never stopped. At present, the manufacturing process of diamond beads mainly includes electroplating, sintering and brazing. Each of the three methods has its own characteristics and scope of application. From the perspective of the use effect, the advantages of the latter two methods are more obvious. The following pictures show diamond beads manufactured by these three processes.

1. Electroplated Bead

The idea of cutting stone on steel wire rope with an electroplated diamond steel ring was put forward by British D.H. Prowse in 1968. The first beads were produced by electroplating, using Co and Ni as electroplating materials, and the diamond was plated on the metal substrate to become a working layer. The electroplating process is simple, reliable, and can be used to make beads with a smaller diameter.

Disadvantages: first, the holding ability of the coated metal on the diamond is limited, and the diamond is easy to fall off in advance, second, the working layer is thin, so the life of the beading rope is short.

These kinds of diamond beads are generally fixed by steel springs, mainly used for mining soft stones such as marble.

2. Sintered Bead

The manufacturing of sintered bead uses the principle of powder metallurgy, the diamond is uniformly mixed with the selected matrix powder or granulated and then combined with the matrix for sintering. Diamond bead sintering is an important process in wire saw production, which directly affects the sawing performance of the wire saw.

Beads are thin-walled cylindrical structures, which require high sintering density. The common hot pressing sintering method directly limits the sintering density of beads due to the thin upper and lower head walls and poor compression capacity, and the head loss is large and the cost is high. The traditional method of cold pressing followed by pressureless sintering leads to lower sintering density of beads, which seriously affects the performance of wire saws.

At present, the most effective sintering method is the hot isostatic pressing(HIP) technology. The application in bead production is to place the sintered beads in the glass jacket and put them into the hot isostatic press(HIP). The inert gas argon is used as the pressure transmission medium, and the temperature rises to 800-900 ℃ for isostatic pressing(HIP) treatment. Then, the glass jacket is removed by roller treatment or shot blasting. The beads produced by this technology have fewer pores and high density, which can improve the hardness, strength, wear resistance and working life of the beads, and can also improve the bonding strength between the blank and the matrix. Due to the large furnace cavity, thousands of beads can be loaded at one time, which is conducive to batch production.

The following table shows the performance comparison of hot pressed sintering and hot isostatic pressing(HIP) sintering samples.

| Performance | Co, Cu Based Matrix | Co, Ni Based Matrix | ||

|---|---|---|---|---|

| Vacuum Hot-pressed Sintering | Hot Isostatic Pressing Sintering | Vacuum Hot-pressed Sintering | Hot Isostatic Pressing Sintering | |

| Bending Strength(MPa) | 1296 | 1363 | 1415 | 1452 |

| Hardness(HRB) | 101 | 101.8 | 108 | 109 |

| Density(g/cm3) | 8.71 | 8.79 | 9.60 | 9.71 |

| Void Fraction(%) | 0.1 | <0.1 | 0.1 | <0.1 |

3. Brazed Bead

The principle of “brazing” of diamond beads is to use brazing filler metal containing active elements (such as Ti, Cr, W, etc.) to make the active elements react with the diamond surface and form a layer of carbide during the brazing process. With the help of this layer of carbide, the diamond, matrix (filler metal), and matrix can achieve a solid chemical metallurgical combination.

In China, nickel-based or titanium-based filler metals are mainly used for brazing beads, and then sintered in a vacuum or argon atmosphere. The diamonds in the brazed beads are arranged regularly and distributed reasonably. Chemical bond bonding and metallurgical bonding coexist. The holding ability of diamonds is strong, the sawing speed is high, and the sawing cost is relatively low. Compared with sintered beads, its service life is less than the latter, but its sawing speed is significantly higher.

Manufacturing Isolation Sleeve

The isolation sleeve is used for spacing and fixing adjacent beads. At present, the isolation sleeves commonly used in the project are washer-type steel spring isolation sleeves, plastic or rubber injection molded isolation sleeves, and the appearance is shown below.

The washer-type steel spring isolation sleeve is the earliest form of isolation sleeve. The biggest disadvantage of this fixing method is the lack of protection for the wire rope. The coolant directly corrodes the wire, and the rock/stone debris entering the spring or even the bead matrix will directly wear the wire rope, greatly shortening the life of the wire rope, and easily causing the saw rope to break.

Therefore, the spring fixation method is mostly used to fix the electroplating beads with short service life and is used in open mining to avoid casualties caused by the breakage of the bead rope.

In order to meet the needs of cutting high-hardness materials, plastic injection-type and rubber injection-type isolation sleeves have been developed.

The isolation sleeve of moulded plastic or rubber type uses wear-resistant plastic and rubber as the isolation pad between diamond beads. The space between the diamond beads and the wire rope is completely filled with plastic and rubber, so as to avoid abrasion of the wire rope due to wear debris entering the space between the bead and the wire rope. The wire rope is well protected from corrosion by coolant, and the service life of the wire rope is increased. In addition, each bead is cast and connected with the steel wire rope. Even if the steel wire rope breaks, the bead is not easy to fly out at high speed to cause accidents. Therefore, it can be used for indoor processing and the demolition of public buildings. To match this, sintered or brazed beads with long service life are mostly used.

Manufacturing Wire Rope

During the use of the diamond wire saw, the wire rope often breaks due to fatigue wear, abrasion, chemical corrosion and other reasons, especially when the processing area reaches a certain amount, the wire breaks more frequently. Broken ropes not only affect production but also bring safety hazards such as throwing beads to hurt people. Therefore, the performance of wire ropes is crucial to the use of bead ropes.

In addition to the performance of the wire itself, the service life of the wire rope is also related to the pre-tightening tension, the minimum curvature of each guide wheel, the axial load of the beads in the process of processing, and the impact load.

At present, the wire ropes used in diamond wire saws made in China are imported from abroad, which are expensive. Therefore, we should vigorously develop wire rope-related technologies for bead wire saws.

Application of Diamond Wire Saw

Diamond wire saws have various applications, mainly in the stone industry (marble, granite) and construction engineering (such as cutting reinforced concrete). For further classification, see the following pictures.

1. Application of Diamond Wire Saw in Stone Processing Industry

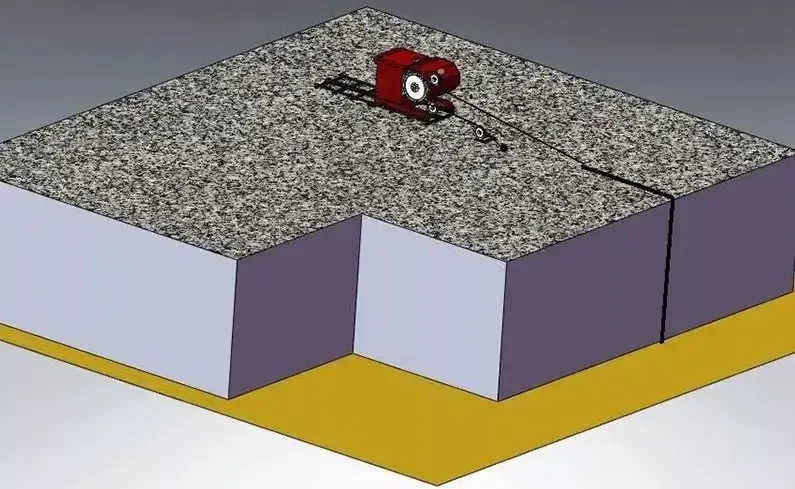

The application of diamond bead wire saw in the stone industry mainly includes stone mining, stone block shaping, stone slab cutting and processing of special-shaped products.

The diamond bead wire saw is used for mining all stones including marble, granite, etc. It has the advantages of high yield, good processing quality, not easy to damage the raw materials, and less pollution in the mining process. It is an indispensable tool for mining at present. According to a report from an American mine, compared with the application of diamond wire saw, the traditional method of mining cracked stone has reduced the production rate by 88%, but increased the cost by 13 times. This is an important reason for the rapid development of diamond wire saws.

The diamond wire saw can process irregular stones that are difficult to process with conventional tools. Therefore, it is widely used in shaping the processing of stone processing plants. Compared with a frame saw and diamond circular saw blades, this technology has higher cutting efficiency and a larger cutting area, and it has low noise and no vibration. It can also perform surface modification and obtain smooth cutting surfaces.

Stone slab cutting is another application of diamond bead wire saw. The diamond single-wire saw is most commonly used to cut very thick stone slabs/plates or small batches of large stone slabs/plates with different thicknesses. The diamond multi-wire saw has incomparable advantages over the frame saw, and it is a promising large stone slabs/plates cutting technology.

The diamond wire saw processing special-shaped stone is one of the CNC stone processing technologies with the highest technology at present. Although it has only developed for nearly 27 years, it has become the main equipment for processing special-shaped stone products with high added value, and the market will continue to expand.

2. Application of Diamond Wire Saw in Construction and Machining Industries

The successful application of diamond wire saws in the construction field has broadened its application field and has developed to a relatively mature stage.

The diamond wire saw is the first choice for green demolition due to its flexibility, convenient on-site installation and movement, no dust, low noise, high efficiency and environmental protection. In addition to traditional reinforced concrete structure cutting, it also has large-scale applications in the fields of submarine cable cutting, oil pipeline cutting, large steel and other metal structures cutting, boiler and smelting furnace transformation, etc. In recent years, there are also new applications, such as cutting hard and brittle materials such as glass and ceramic components with bead wire saws.

Based on practical experience, Dymend Tools has obtained a lot of data and supplemented an article on the applications of diamond wire saws↗

Frequently Asked Questions When Using a Diamond Wire Saw

The large-scale application of diamond wire saw from its birth to the present has only passed for decades, but it has entered many industries at a rapid speed and exerted its unique advantages. Although a considerable number of scholars in the world have carried out experimental or engineering research on its related technologies, the research scale is not large, the depth is not enough, and a systematic academic theory has not yet been formed.

Therefore, with the increasing application of diamond wire saw technology, its problems have been exposed one after another. Dymend has sorted out the most frequently asked questions in the use of diamond wire saws.

- Frequent wire rope breakage.

- The matrix is stripped from the steel ring.

- Poor fixation effect of diamond beads.

- Diamond beads fall off.

- Diamond wire saw partial grinding.

- The diamond wire saw is not sharp enough.

- The service life of the diamond wire saw is too short.

- The performance of the diamond bead matrix does not match the cutting object.

- The mismatch between matrix wear and diamond wear.

- Abnormal shedding of diamond abrasive grains on beads.

- Large changes in processing parameters.

- The small diameter of beads.

- Weak chip removal ability during diamond wire saw cutting.

These problems seriously restrict the further development of diamond wire saws.

Therefore, it is quite necessary to further carry out systematic research on the diamond wire saw, which is also the premise and foundation to break through the current technical bottleneck.

But developing new materials may take a long time, how can we avoid these problems with the current use of diamond wire saws? In fact, choosing the right diamond wire saw is the beginning of everything beautiful, and it can also avoid many problems in use.

Three key points for selecting the right diamond wire saw:

- Select from the most common diamond wire saws on the market↗

- Select the correct length of the diamond wire saw↗

- Select the appropriate diamond bead diameter and quantity per meter↗

Of course, Dymend also summarized some corresponding measures for correctly using the diamond wire saw.

How to Use Diamond Wire Saw Correctly

Because the diamond wire saw needs to run at a high speed when it is used, non-standard operation or product quality problems will lead to a series of cutting problems and failures. Dymend‘s following suggestions can effectively solve and avoid these problems.

1. Safety Protection

When the diamond wire saw is used at high speed, the operator is not allowed to stand in or near the sawing path.

2. Cooling

When using the diamond wire saw, it is necessary to ensure that the rope in the saw path is in a cooling state, otherwise, the isolating sleeves(such as rubber, or plastic) will overheat, affecting the fixing effect of the diamond beads.

3. Storage

When the diamond wire saw is not in use, it should be stored in a cool and dry place to avoid heavy pressure or tension.

4. Loose Diamond Beads

- When cutting, the local bending radius of the wire rope is too small, and the bending stress is too large, which causes the diamond beads to detach from the isolating sleeves(rubber, plastic, or steel spring), losing the fixation ability of the isolating sleeve to the diamond beads, and the diamond beads are easy to loose.

- The cooling water is not in place or the cooling effect is not sufficient, the isolating sleeves(such as rubber, or plastic) are overheated and aged, and the fixation ability of diamond beads is lost, which is easy to cause diamond beads to loosen.

- If the diamond wire saw is jammed, it should avoid strong pulling and twisting, otherwise, the diamond beads are easy to be pulled off and become loose.

5. The Diamond Wire Saw is Broken

- The wire rope breaks from the steel coupling/joint: often the steel coupling/joint and the wire rope are not compacted tightly, or the steel coupling/joint compaction method is incorrect, which causes the wire rope to detach or break from the steel coupling/joint.

- The wire rope does not break from the steel coupling/joint: it is often due to the loose diamond beads that the surface of the wire rope is quickly worn off under high-speed rotation, which reduces the strength of the wire rope and leads to wire rope breakage. Once the loose diamond beads are found, cut off two beads at the loose place and then reconnect them, or tighten the loose beads to prevent them from rotating, which can avoid wire rope breakage.

6. Cracking or Falling of Isolation Sleeve

- All conditions mentioned in the above “Loose Diamond Beads” are easy to lead to isolation sleeve(rubber, plastic, or steel spring) cracking.

- Check the rubber wear of the guide wheel to prevent the diamond wire saw from slipping on the rubber wheel. The wire rope is overheated due to no cooling protection, and the isolation sleeve(rubber, plastic, or steel spring) is easy to come off.

7. Diamond Wire Saw Partial Grinding

- The diamond wire saw should be twisted several times before use. If the number of twisting circles is not enough, the twisting force of the wire rope will be far less than the cutting stress, and the diamond wire saw is difficult to deflect circumferentially, which is easy to cause partial grinding.

- When the diamond wire saw is cutting, the wire rope feed is too fast, the cutting stress is far greater than the normal torsion force, and the wire is prone to partial grinding.

In order to provide a detailed explanation of the use of diamond wire saws, we have written a specific operation article: How to Use Diamond Wire Saw Correctly↗

the Top 5 Diamond Wire Saw Manufacturers

In addition to the standard operation that can ensure the normal use of diamond wire saw, a good supplier of diamond wire saw is also very important, because quality, price, supply capacity and after-sales service are often the reference indicators when selecting diamond wire saw.

At present, diamond wire saw manufacturers are mainly concentrated in five regions:

- Italy: the origin of diamond wire saw. Product technology and quality have always been in the leading position in the industry, but the price is also relatively expensive. The multi-wire saw is an advantageous product (can manufacture a very advanced multi-wire saw with a diameter of 3.2mm), which is very suitable for the cutting and processing of luxury stones.

- China: China is a huge stone producing country, which has driven the prosperity of the diamond wire saw industry with its huge local stone processing volume. At the same time, with the maturity of the supply chain of raw materials such as Henan Huanghe Whirlwind Co., Ltd., Zhengzhou Sino-Crystal Diamond Co.,Ltd., Zhongnan Diamond Co., LTD, and Zhengzhou Research Institute For Abrasive & Grinding Co., Ltd.(ZZSM), China’s diamond wire saw is not only of good quality, but also benefits from the advantages of the supply chain, and the price is relatively reasonable, which is very suitable for the use of ordinary marble and granite mining, the technology in high-end wire saw has accumulated a certain amount of technology, but it still needs further exploration comparing to Italy diamond wire saws.

- Turkey: Turkey’s diamond tool industry is mature, and many enterprises are engaged in the research, development and production of diamond wire saws. The famous one is Hartek Mermer. However, Turkey does not have a complete supply chain of the raw materials industry like China. In addition, Turkey’s currency has depreciated in recent years, and the cost of imported raw materials is high, leading to the continuous rise in the production cost and price of diamond wire saws in Turkey, technology development and quality of diamond wire saw are limited by the stability of raw materials.

- India: India is the country with the largest consumption of diamond tools at present, and the demand for ultra-hard cutting materials is increasing. The products of the local diamond wire saw manufacturers in India cover all kinds of cutting ropes, and they can even sell diamond beads, wire ropes, connectors, etc. separately for customers to assemble. The wire saw in India is very cheap, but the diamond micro powder and matrix metal powder used are relatively low-grade, and the technology research and development is not mature enough, which is more suitable for the demand of the low-cost market.

- Korea, Japan: In the field of precision manufacturing, Korea and Japan will never be absent. Korea and Japan are very advanced in diamond tool technology. They have even started to apply diamond tools in batch to precision processing areas such as automobiles and semiconductors. Research and development of diamond wire saws are also very advanced. The famous manufacturers are Shinhan Diamond and EHWA Diamond. However, as Korea and Japan are also limited by the industrial supply chain, they gradually lose their advantage in capacity and market competition and even invest in factories in China to make up for this shortage.

Overall, for the choice of diamond wire saw manufacturers, high-end wire saws & luxury stone processing, Dymend recommends Italian manufacturers, in the case of ordinary stone processing & heavy consumption of diamond wire saws, we recommend Chinese manufacturers, in the low-price market, we recommend Indian manufacturers.

Based on the industry’s geographical distribution and our more than 10 years of experience, Dymend recommended the top 5 manufacturers/suppliers for choice.

Ⅰ Pellegrini Meccanica Spa from Verona, Italy

Pellegrini Meccanica Spa is a group enterprise, including Pellegrini The Stone Master (diamond wire saw and machine equipment), Marmomachine Pellegrini (stone surface treatment equipment), Eurosolvevamento Pellegrini (stone and concrete crane) and Pellegrini Beton Division (concrete processing equipment). About three centuries ago, the Pellegrini family mined “Rosso Verona” marble in Sant’Ambrogo di Valpolicella, and 60 years ago, the first automatic equipment was designed and assembled by Marco Pellegrini, an engineer. From then on, the mining road of diamond tools and machinery began. Today, the company is headed by Dr. Elena Pellegrini.

The product advantage of Pellegrini Meccanica Spa is that it provides high-quality diamond wire saws, at the same time, it has also developed the corresponding machinery, and almost covers all production and processing scenarios, mainly including POLYONE series (diamond multi-wire saws), TRIMWIRE series (mining wire saws), LA ROSSA SCANNER series (stone surface treatment), DIAMANTFIL series (stone block cutting wire saws), MAGICFIRE 16 series (block cutting into stone slabs), etc. The technical level is in the leading position in the world.

Ⅱ CO.FI.PLAST SRL from Lessolo, Italy

CO.FI.PLAST SRL belongs to the Brocco group. The Brocoo group has been engaged in granite mining since 1966. After realizing the importance of automatic processing, the Brocco group established CO.FI.PLAST SRL in 1984, and began to develop and produce diamond wire saws for stone processing. In order to support the use of diamond wire saws, the Brocco group established WIRES ENGINEERING in 1997, which specializes in designing and producing diamond wire saw cutting machines.

The diamond wire saw of CO.FI.PLAST SRL has good cutting efficiency, stone production rate and cutting stability, reducing the stone processing cost. The perfect cooperation between the diamond wire saw and the wire saw also improves the cutting accuracy. At present, CO.FI.PLAST SRL has expanded the versatility of diamond wire saws, which can also be used for cutting concrete and construction industries in addition to the stone industry.

Ⅲ Skystone Diamond Tool Co., Ltd. from Fuzhou City, China

Skystone Diamond Tool Co., Ltd. founded in 2003, currently has two factories for manufacturing diamond wire saws and stone equipment. Its product series include stone processing wire saws, multi-wire saws, mining wire saws, reinforced concrete wire saws, etc. The product performance is excellent. In addition to being used locally in China, diamond wire saws are also exported to Brazil, Iran, Norway, South Africa, Turkey, Russia, Poland and other countries, and set up an office in Brazil.

Skystone’s diamond wire saws have excellent performance, compared with Italian manufacturers, it has a certain cost performance while ensuring quality.

Ⅳ Dymend Tools Co., Ltd. from Quanzhou City, China

Dymend Tools Co., Ltd., founded in 2012, is located in Quanzhou city, China’s largest stone base. Taking advantage of the local stone industry, it has developed rapidly and launched a series of diamond wire saw products, including diamond beads, diamond rubber wire saws, diamond plastic-injection wire saws, diamond spring wire saws, and diamond multi-wire saws. The products are suitable for mining granite and marble, stone processing and shaping in stone factories, and reinforced concrete cutting in the construction industry. In addition to providing products, Dymend advocates solution-based services, it also provides a series of equipment, accessories, consulting and after-sales services. After more than ten years of development, the products are sold to more than 30 countries, including Brazil, Spain, Poland, Türkiye, Vietnam, Iran, Pakistan, etc.

Dymend’s products have great advantages in quality, price and sales services. At present, there are more than 30 R&D engineers and more than 20 sales engineers, not only providing products but also providing solutions.

Ⅴ Madras Diamond Tools from Tamil Nadu, India

Madras Diamond Tools was founded in 1990 and has a certain popularity in the Indian market. Its products include diamond wire saws and diamond beads. The products are mainly exported to the United States, Nepal, Australia, Russia, Egypt and other countries. The products are very competitive in price.

Development of Diamond Wire Saws in China

Compared with the international level, China’s diamond wire saw started late, although after nearly 30 years of development, its application is still very narrow. China is a big country in stone mining, and the application of diamond wire saw in stone is more mature than that in other fields.

In China, a small part of diamond wire saws is used for marble mining, while the rest are used primarily for shaping and segmentation of blocks and processing of special-shaped stones. In the field of building construction, diamond wire saws are less involved, and there is a blank in the processing of hard and brittle materials such as glass and composite wood plates and steel parts.

With the development of infrastructure and stone mining in China, the research and production capacity of diamond wire saws in China has made great progress. A considerable number of manufacturers have made their presence in the domestic and international markets. For example, Skystone, Dymend, TEBON, etc. introduced above have replaced the originally imported diamond wire saws with excellent quality and competitive prices.

At present, Chinese diamond wire saw manufacturers mainly focus on the following 5 issues:

- Prevent excessive vicious competition from causing the price to plummet and damaging the benefit of the industry.

- The diamond wire saw must be made with strong pertinence to meet different user needs.

- Develop new alloy powder suitable for diamond beads, and adopt advanced sintering technology.

- Speed up the development of a diamond wire saw with a small diameter.

- Develop domestic and international markets.

Development Trend of Diamond Wire Saw

Ⅰ Reduce the Diameter of Wire Rope and Diamond Beads

In the beginning, the diameter of the wire rope core used by the diamond wire saw was 5.0mm, and the diameter of the diamond bead was 11.0mm. At present, the most advanced diamond bead wire saw in the world uses only 2.8mm wire rope core diameter and 3.2mm diamond bead diameter.

Reducing the diameter of diamond beads is mainly used in the field where the size of the cutting seam is strictly required, especially for the cutting of precious stones. The application of small diameter diamond wire saw in stone processing, on the one hand, can save stone resources and reduce costs, on the other hand, can reduce processing energy consumption, improve production efficiency, and make processing means more environmentally friendly.

Due to the reduction of cutting resistance, the small diameter diamond wire saw can cut large areas (4m2) and very thin granite slabs(thickness 5mm), and the sawing efficiency is increased by 3 times. Compared to the diamond saw blade with a diameter of Φ9mm, the cutting force and energy consumption ratio of a small diameter wire saw reduces by about 20%~30%, and the cutting time per square meter reduces by about 25%. The size deviation of material processed by small diameter wire saw is also smaller than that of large diameter diamond wire saw, so it has some special properties.

At present, small-diameter beads are best made by hot isostatic pressing (cold pressing followed by hot isostatic pressing sintering) or brazing diamonds.

Ⅱ Increase the Number of Diamond Wire Saws

Using multiple diamond wire saws to cut stone is to use multiple diamond wire saws to cut stone blocks into big rough boards and thick slabs at the same time. This technology has been developed so far and is known as the diamond multi-wire saw.

Compared with a single diamond wire saw, diamond multi-wire saws have obvious advantages of high production efficiency. The processing of granite can reach 250m2/24h, which can quickly change the thickness of the stone slabs or the cutting location in the block. At present, up to 80 diamond wire saws can be installed side by side, which is the latest development of diamond multi-wire saw technology and represents the latest technology of diamond wire saws.

Ⅲ Automatic Sawing & Cutting

Computer numerical control (CNC) is used to control the sawing process without supervision. It is worth noting that the cooling water is automatically recycled. The water consumption of a diamond wire saw during operation does not exceed 68.1L/min. This is extremely advantageous in terms of cutting efficiency, labor cost and environmental protection.

Conclusion

At present, diamond wire saws are gradually widely used in the stone industry. Many stone production plants have introduced advanced technology and equipment. They use diamond wire saws to mine stone materials and process slabs/plates of various shapes (mainly special-shaped slabs/plates). It has the advantages of high production efficiency, good product quality, low cost, etc., which reflects the new development of modern industrial production technology. It is important to obtain high-quality stone blocks and slabs of various shapes, It is of great significance to improve the processing quality, production efficiency and economic benefits of stone materials.

It can be seen from the current application and development of diamond wire saw that its technology will develop towards the direction of small-diameter diamond wire saw, multi-wire saw and sawing automation, which can save both processing materials and processing energy. Brazing technology can improve the holding ability of solder to diamond, so as to solve the problems such as serious abnormal shedding of diamond abrasive and low utilization rate caused by the poor holding ability of diamond abrasive particles by the matrix under the traditional manufacturing process, which is expected to improve the cutting performance of diamond beads again.

As far as its application prospect is concerned, in addition to the stone processing field, the application proportion of diamond wire saw in the demolition of building components, road pipeline construction and other projects will be greatly increased in the future. Using the diamond wire saw to cut large metal components, glass and other hard and brittle materials is also expected to become a research and development hotspot.