- Tensioning Force of Diamond Wire Saw

- Pre-loading Rotation of Diamond Wire Saw

- Connecting Methods and Requirements of Diamond Wire Saw

- Sharpen the Diamond Wire Saw

- Cutting Direction of Diamond Wire Saw

- Mixed Use of Diamond Wire Saws with Different Wear Levels

- Replacement Requirements and Methods for New and Used Diamond Wire Saws

- Linear Speed of Diamond Wire Saw

- Add Cooling Water

- Maintenance of Diamond Wire Saw

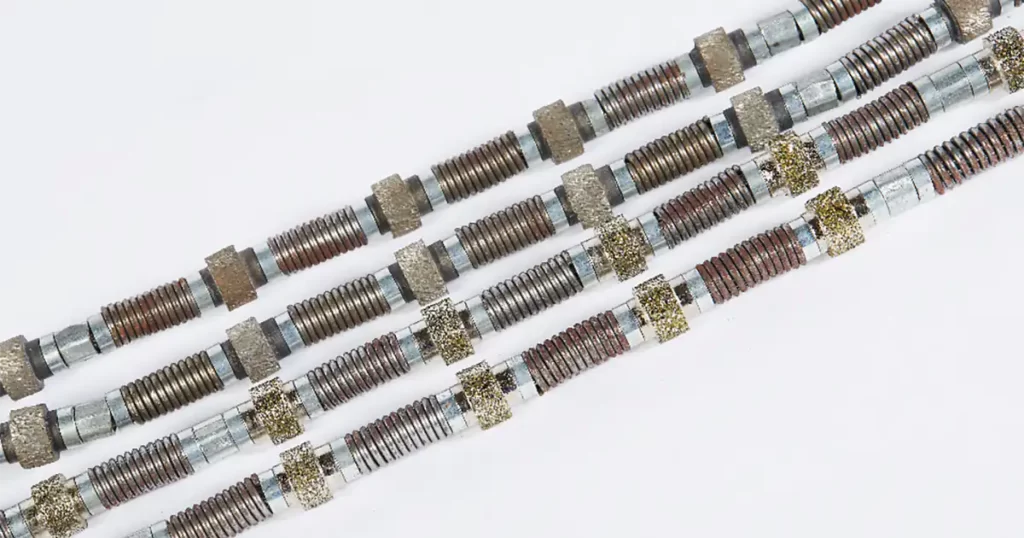

When using the diamond wire saw to cut stone, only by using the diamond wire saw correctly can the maximum cutting efficiency and cutting life of the diamond wire saw be guaranteed and the cutting cost be reduced.

The methods for the correct use of diamond wire saws include: appropriate tension control, preloading of plastic injection diamond wire saws, connection methods for diamond wire saws, requirements for the alternate use of new and used diamond wire saws during the cutting process, requirements for the mixed use of new and used diamond wire saws, maintenance, repair of diamond wire saws, and the correct placement of cooling water.

Tensioning Force of Diamond Wire Saw

Because diamond wire saws are flexible cutting tools, appropriate tensioning forces must be applied to diamond wire saws during use to make them both rigid and flexible, in order to ensure their optimal cutting efficiency, best-cutting quality, and longest service life. The amount of tension applied to a diamond wire saw is related to some factors, such as the application of the diamond wire saw, service length, diamond wire saw structure, the diameters of the diamond beads and wire rope, and the length of the cutting surface.

When cutting stone slabs and special-shaped stone products, in order to ensure good surface and shape quality of the cutting objects, it is necessary to maintain a relatively high rigidity of the diamond wire saw during cutting, and minimize the vibration of the diamond wire saw. Therefore, a relatively large tensioning force should be applied to the diamond wire saw. Diamond wire saws used on fixed cutting equipments/machines such as rough stone block shaping machines or stone special-shaped machines typically have a cutting surface length of 1.2-4m, a wire saw the length of 16-24m, and a diamond bead diameter of 8.7-9 2 mm, with a wire rope diameter of 3.5~4.8mm. The diamond wire saw is of a plastic injection structure, and the tension acting on each pair of diamond wire saws is generally around 3000~6000 N.

When mining or shaping rough stone block, although the cutting area is larger and the diamond wire saw used is longer, but the quality requirements of the cutting surface is relatively lower. In the cutting process, with the cutting area in the gradual reduction, diamond wire saw length because of the reduction of the cutting surface and cutting position change, also in the continuous change. Therefore, when mining or shaping rough stone blocks, even using diamond bead diameter 11~12mm and wire rope diameter 4.9mm, also can use relatively low tension force. This not only will not affect the diamond wire saw cutting quality and efficiency, but also will reduce the diamond wire saw breakage opportunities.

Pre-loading Rotation of Diamond Wire Saw

Before connecting the plastic injection diamond wire saw into a closed cutting ring, it is necessary to apply pre-load rotation to the diamond wire saw before connecting. Because the diamond beads of the plastic injection diamond wire saw are fixed on the steel wire rope, if not pre-load rotation, only by the natural rotation of the steel wire rope, is not able to make the diamond wire saw in the cutting process to maintain the autorotation, the result will lead to diamond bead outer circle of a side always contact with the cutting surface, make the diamond bead single side excessive wear (also known as partial grinding), which will reduce the service life of the diamond rope saw. The function of pre-load rotation is to ensure that when cutting, the wire rope with diamond beads around its own axis non-stop rotation, so that diamond beads wear evenly.

For spring type diamond wire saw, the diamond beads and wire rope are rotatable between them, so there is no need to preload the rotation before connecting the spring type diamond wire saw into a closed ring, which can also ensure that the diamond beads can rotate freely during the cutting process and there will be no bias grinding of the diamond beads.

Diamond wire saw preload rotation of the number of turns by the length of diamond wire saw, new and old degree decision. Diamond wire saw in the fully new or almost new situation, pre-load rotation of the lap number can be appropriately reduced, in order to reduce after many times use of the diamond wire saw fatigue, on the wire saw rotation ability to bring the impact, the used diamond wire saw pre-load rotation lap number to increase accordingly. Usually, each meter diamond wire saw should preload rotation 1.5-2 turns.

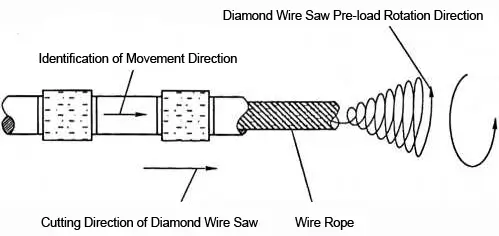

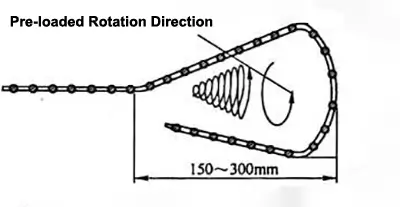

The below diagram is the diamond wire saw pre-load rotation diagram.

After Dymend Tools‘ test, the below table shows the relationship between the number of connectors changed and the number of preloaded rotational turns for the use of sintered diamond bead plastic injection wire saws recorded in mines for reference. The purpose of changing the number of diamond wire saw rotation turns in the experiment is to make the diamond beads in cutting the working angle, and the position of the contact point with the ore body often changes, to ensure the uniform consumption of diamond beads along its circumference, to avoid diamond beads always stay in the same face sawing, the formation of diamond beads of partial wear scrap.

| Replacement Connector Sequence | Service Life/h | Increase/Decrease Cycles Per Meter of Diamond Wire Saw | Actual Preload Rotations Per Meter of Diamond Wire Saw |

|---|---|---|---|

| First Time | 40-50 | – | 2 |

| Second Time | – | 0.5 | 2.5 |

| Third Time | – | -0.5 | 2 |

| Fourth Time | – | -0.5 | 1.5 |

| Fifth Time | – | 0.5 | 2 |

| Sixth Time | – | 0.5 | 2.5 |

Connecting Methods and Requirements of Diamond Wire Saw

The diamond wire saw connection method is related to its structure, injection type diamond wire saw and spring type diamond wire saw connection method is different.

Connection of Plastic Injection Diamond Wire Saw

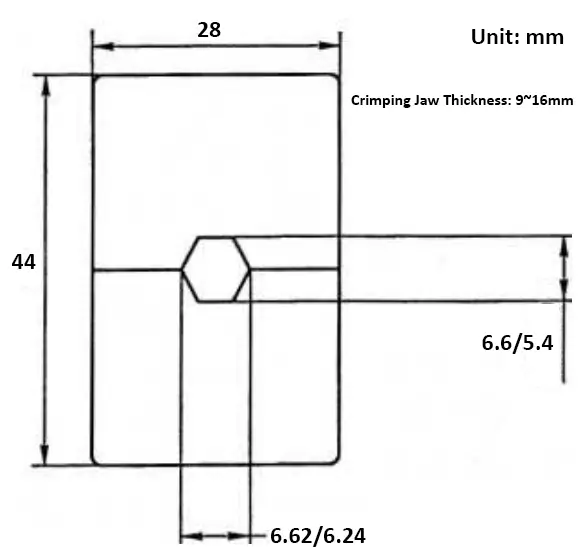

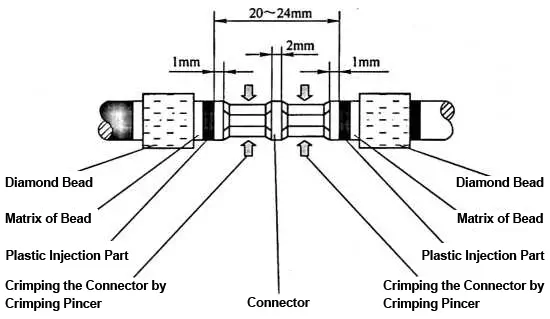

Based on the actual test results of Dymend Tools, we introduce the connection method, operation steps, and connection requirements of plastic injection diamond wire saws, connectors for fixed shaping machines and special-shaped cutting machines. The connector length is 21 mm, and the wire rope diameters of the diamond wire saw are 3.9 mm and 4.9 mm. The following picture shows the shape of the crimping jaw and the reference dimensions of the crimping jaw suitable for the two diameters of steel wire rope.

Depending on the size of the jaws of the crimping equipment, the thickness of the crimping jaw can be 9 mm to 16 mm. 16 mm thickness of the crimping jaw can be used to crimp the two connectors of wire rope at the same time. 9 mm thickness of the crimping jaw can only be used to crimp a single connector at a time, it needs to crimp twice if want to connect one wire rope.

A. Preparation Before Crimping Diamond Wire Saw

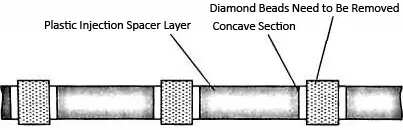

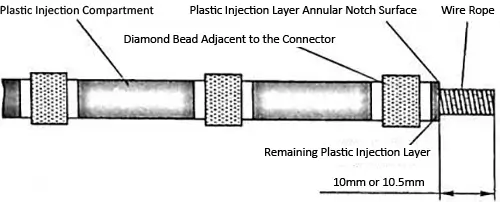

According to the different number of diamond beads assembled per metre of diamond wire saw, as well as the connector length size (usually 21mm), determine the length of the diamond wire saw connecting part pre-dimensioned. To granite mining diamond wire saw for example, commonly used 40 diamond beads per meter, when using 10mm length diamond beads, the plastic injection spacing layer length is about 15mm, if is currently the most number of diamond beads per meter diamond wire saw, 42 diamond beads per meter, the plastic injection spacing layer length is 13.5 mm. Because two diamond beads cannot accommodate the length of a connector, the plastic injection spacer between each two diamond beads can only be used for connector at one end, and one diamond bead must be deleted The picture below shows a diagram of the plastic injection layer in the joint area of a diamond wire saw.

When carrying out diamond wire saw shearing operations, the side of the diamond bead that needs to be removed can be cut first, then the 10mm (connector length 20mm) or 10.5mm (connector length 21mm) plastic injection layer can be removed in a loop, the remaining plastic injection layer between the cut and the next diamond bead must be retained. Diamond saws must be cut using a crescent-shaped crimping pincer, not using a straight-edge crimping pincer, not to mention hacksaws or chisels and other tools to ensure that the wire rope is neatly cut and flat and that the wire rope does not lose strands. Steel wire rope is neatly cut off, according to the need, can be appropriate to repair the end of the wire rope, remove the end of the wire burr and make the end surface flat. Attention should also be paid to keeping the cutting surface of the injection layer flush, and not hurting the core of the wire rope. The following is a diagram of the diamond wire saw cutting-off treatment.

When connecting the spring type plastic injection diamond wire saw, first use pliers to loosen the spring in the joint part, that is from the joint end face to the length between the plastic injection layer cutting surface, and cut the spring off along the plastic injection layer cutting surface, then remove the plastic injection layer. Both the plastic injection layer and the spring between the cut side of the plastic injection layer and the adjacent diamond beading must be retained.

If possible, the end of the diamond wire saw should be cleaned with tri-gas vinyl to remove plastic residue and other impurities, blow dry and then proceed with the connecting operation. In short, the connection area must be cleaned.

B. Pre-loaded Rotation Method for Diamond Wire Saw

In a relatively clean site for diamond wire saw pre-load processing, need two people cooperate to make the diamond wire saw straight, each person respectively from the diamond wire saw ends about 150-300mm in length part of the folded bent into a circular arc, easy to hold firmly, where the other person will diamond wire saw end along the direction of rotation of the wire rope (counterclockwise rotation), according to the length of the connected diamond wire saw, according to Pre-loaded rotation of 1.5 to 2 turns per meter. Before the diamond wire saw is connected, it must be kept in preloaded condition and cannot be loosened, care should also be taken not to damage the steel wire at the end of the diamond wire saw during the rotation.

C. Crimping the Connector of the Diamond Wire Saw

Insert the exposed part (10mm or 10.5mm long part) of the steel wire rope at both ends of the diamond wire saw in the preloaded rotating state into the connector, and place the connector in the crimping jaw for crimping. Pay attention to the position requirements between the connector and the crimping jaw during crimping. When using a wide crimping jaw, when completing the connectors crimping at one time, the connectors should be placed in the center of the crimping jaw and then crimped. When using a narrow crimping jaw, it should be crimped twice, the method shown in the following diagram should be followed.

Because the crimping jaw currently in use is of a positive hexagonal structure, it is best to crimp successfully in one pass. If it really needs to complete crimping in stages, after the first crimp, you can rotate the connector 60 °, according to the above method, and then crimp again, at most, it can be crimped 3 times because if it is crimped many times, it will make the connectors and the steel wire rope between the emerging gap, reduce the combination of the two forces.

When using a long crimping jaw, the connector is crimped at one time. It should be noted that the crimping jaw should be located in the middle symmetrical part of the connector, and a flange of 1~2mm should be left between the two sides of the crimping jaw and the ends of the connector.

When using a narrow crimping jaw, only half of the above crimping is completed. Repeat the operation to complete the other half of the joint crimping. Note that a 1mm flange is left between the two ends of the crimp jaw and the connector, and a flange should also be left in the middle of the connector.

After crimping, the following points need to be noted:

- Between the connector and plastic injection layer does not allow any gap, otherwise diamond rope saw easy to wear off from the gap.

- If the end of the wire rope in the connector is not placed in the center, will cause the connector and wire rope crimping friction between the reduction, serious will cause the wire rope slip off.

- If the crimping pressure is too high, will cause excessive extension of the connector, easy to produce fatigue fracture.

- If the crimping pressure is not enough, will cause the connector to slip off or brittle break.

- Try to make the diamond bead and the joint to maintain more than 5mm between the plastic injection layer, in order to avoid the wire rope is soon abraded and fracture.

- If the shear surface of both ends of the connector is not flush, it must be regrinded, otherwise it will make the wire rope lose 1~2mm effective bonding length and reduce the tension force that should be borne.

In order to avoid the above problems, must be strictly in accordance with the procedures and requirements of the connection of diamond wire saw connection operation.

D. Determination of Crimping Force

When crimping wire rope diameter of 4.9mm diamond wire saw, can use 60~80kN crimping force, wire rope diameter of 3.9mm, crimping force is about 40~50kN. crimping granite with diamond wire saw, can use crimping force of 200kN hydraulic tools, crimping marble with diamond wire saw, can use crimping force of 100kN hydraulic tools.

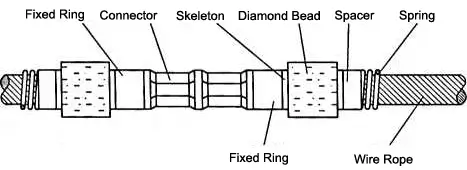

Connection of Spring Type Diamond Wire Saw

When connecting electroplated diamond wire saws, the connectors’ position is usually chosen between two adjacent sets of diamond beads, i.e. the connectors are fixed on both sides of the fixing ring. Because the spring type diamond wire saw in the assembly must be pre-crimped, if the connectors’ position to choose in need of pre-crimping diamond beads between, because in the mining site generally can not be equipped with assembly workbench, manual to diamond bead assembly for pre-crimping is very difficult, even if can complete pre-crimping connection, pre-crimping size can not be controlled very accurately, so that after the connection of the spring type diamond wire saw is not achieve the best cutting condition. The connector crimping requirements are the same as for plastic injection diamond wire saws. The following diagram is a schematic diagram of the connector crimping for spring type diamond wire saws.

There are currently many types of crimping tools for diamond wire saws, which should be used with reference to the corresponding user manual. After purchasing diamond wire saws produced by different manufacturers, you must use the connectors provided by that manufacturer, and confirm with the manufacturer whether the crimping tools, crimping jaws, and pliers provided with the diamond wire saw are suitable before using them. Usually, it is prohibited to mix connectors with diamond wire saws from different manufacturers.

Sharpen the Diamond Wire Saw

Most diamond wire saws are processed to increase their sharpness and expose diamond particles before leaving the factory. Such diamond wire saws generally do not require sharpening edge treatment before use, and can quickly enter a sharp cutting state once used. There are also some diamond wire saws that have not undergone sharpening treatment after leaving the factory, and such diamond wire saws must undergo sharpening treatment before use.

Ordinary refractory bricks can be used to increase the sharpness of diamond wire saws. It should be noted that when using refractory bricks to increase the sharpness, cooling water should not be directly poured onto the refractory bricks, otherwise the refractory bricks will quickly wear out, affecting the sharpness, and wasting the refractory bricks. At the initial stage of cutting, it is also possible to use a linear speed and feed rate that are 20% lower than the normal value as cutting parameters to cut some soft and easy to cut stones, in order to increase the sharpness of the diamond.

Generally speaking, it is recommended to use a linear speed of 20 to 21m/s for increasing the sharpness of diamond wire saws used for granite cutting, and a linear speed of 26 to 28m/s for increasing the sharpness of diamond wire saws used for marble cutting. The best sharpness state is that when you touch the diamond beads with your fingers, you feel like scratching your hand. After increasing the sharpness of the diamond wire saw, the cutting parameters of the diamond wire saw can be adjusted to the normal cutting state.

There are some new diamond wire saws whose diamond beads have been treated to increase their sharpness, but when manufactured, their outer surfaces are wrapped in plastic injection or rubber injection seals. This diamond wire saw can directly perform cutting operations, but at the beginning, by appropriately increasing the linear speed of the diamond wire saw and reducing the feed speed, the rubber or plastic injection seal layer on the surface of the diamond bead will be quickly removed, and then cutting can be performed according to normal parameters.

Cutting Direction of Diamond Wire Saw

When mining and cutting the horizontal plane, the diamond wire saw usually moves in a clockwise direction, and can also move in a counterclockwise direction according to the actual situation of the site.

When mining and cutting the vertical plane, the diamond wire saw moves from bottom to top. At this time, the cooling water is brought into the saw slot by the diamond wire saw from the bottom to the top. Due to the effect of gravity, the cooling water can increase the time it stays in the saw slot, improving the cooling effect on the diamond wire saw. It also facilitates the discharge of chips. If a diamond wire saw is used to cut from top to bottom, powdery chips will deposit downward in the lower cutting seam, causing the seam to become clogged.

If the bottom of the cut surface is open during mountain disassembly or rough stone block shaping and cutting, the diamond wire saw can be used to move from top to bottom as needed during vertical cutting. The open bottom surface will not cause chips to deposit and block the saw gap, but instead will facilitate the cooling water to be carried as far as possible to the deeper bottom saw gap position by the diamond wire saw. When using the motion direction of this diamond wire saw, it is necessary to take protective measures in the motion trajectory direction of the diamond wire saw.

Generally, the cutting direction of the diamond wire saw is marked on the plastic/rubber injection layer. Even diamond wire saws that have not undergone sharpness enhancement processing are mostly marked with the cutting direction. Therefore, before using a diamond wire saw, it is necessary to first identify the cutting direction marks of the diamond wire saw and make the cutting direction of the marks consistent with the actual cutting direction. If the cutting direction is incorrect, especially if the cutting direction of the diamond wire saw that has been processed to increase its sharpness is used incorrectly, it will affect the service life of the diamond wire saw and waste a lot of time due to increase sharpness again.

Once used, the cutting direction of a diamond wire saw cannot be changed each time it is used. If the cutting direction is changed midway, it may cause a large amount of diamond on the surface of the diamond bead to fall off, reducing the service life of the diamond wire saw. Even more, it may cause a hardened layer to appear on the surface of the diamond bead, making it impossible for the diamond wire saw to cut the stone again, and it is necessary to conduct a new sharpening treatment. In practice, it has been found that once this kind of hardened layer occurs due to the incorrect use of a diamond wire saw in the cutting direction, it takes a lot of time to polish and move it. Using refractory bricks to remove this layer takes 5 to 6 times the time required for ordinary sharpness enhancement processing, or even longer.

With the growth of the use time of the diamond wire saw, sometimes the direction marks on the plastic/rubber injection layer will be worn away, which requires that after each cutting of the diamond wire saw, the cutting direction of the diamond wire saw should be marked with plastic tape to avoid confusion. If the cutting direction of a diamond wire saw cannot be identified due to an error in operation and the marking is forgotten, the cutting direction can also be determined by the wear shape of the diamond beads. Usually, the movement of a diamond wire saw is from the end with the bigger diameter of the diamond bead to the end with the smaller diameter. The following picture shows the cutting direction and direction marking of the diamond wire saw.

Mixed Use of Diamond Wire Saws with Different Wear Levels

In practical use, especially in stone mining, due to the transformation of the cutting surface and the constant change of the cutting position, there will be many remaining diamond wire saws with different lengths and varying degrees of wear, and these diamond wire saw often still have a certain service life. Therefore, they can be mixed and connected together for continued use to ensure the maximum service life of the diamond wire saws.

The mixed use of diamond wire saws must comply with the following principles: the same structure type, the same number of diamond beads per meter, the difference in diameter of diamond beads within 0.1 to 0.2 mm, and the same diameter of wire rope.

On the contrary, the following diamond wire saws cannot be mixed:

- Electroplated diamond wire saws and sintered diamond wire saws cannot be mixed.

- Plastic Injection type, spring type, spring and plastic injection type, or rubber injection type. Diamond wire saws of different structures cannot be mixed.

- Diamond wire saws with and without sharpness treatment cannot be mixed.

- The new diamond wire saw cannot be mixed with the old diamond wire saw.

Why is this?

This is because when diamond wire saws with large diameter differences are mixed, the diamond beads with large diameter will be quickly worn, even broken or broken in a short time. After connecting a diamond wire saw that has not undergone sharpness enhancement treatment with a diamond wire saw that has undergone sharpness enhancement treatment, the rubber or plastic injection seal layer of the new rope has not been removed, and the diamond beads have not undergone sharpness enhancement treatment. The rubber or plastic injection seal layer with high friction will encounter significant resistance during cutting, which can easily generate heat, and the rubber injection rope may be pulled off as a result, plastic softening may occur in the plastic injection rope, and diamond beads compress the plastic spacing and gather together, thereby damaging the diamond wire saw.

Replacement Requirements and Methods for New and Used Diamond Wire Saws

In mining operations, when the cutting surface enters the final stage, it is necessary to replace the currently used diamond wire saw with a used/old diamond wire saw. This is because in the final stage of cutting, especially in the final stage of horizontal cutting, the connection area between the ore body and the separation body is relatively small, and the steel wedge inserted between the horizontal planes alone is not sufficient to support the separation body, making it difficult to ensure that the separation body does not collapse, leading to an accident where the diamond wire saw is pressed into the saw slot and discarded. Especially for ore bodies with relatively large fissures, local collapse of rocks in separated bodies is often encountered. Even if it is vertical cutting or rough stone block shaping cutting, it may be caused by the occurrence of side sliding and tipping of the separation body, resulting in the diamond wire saw being pressed into the saw gap and being scrapped. If a new diamond wire saw or a diamond wire saw with a certain service life is used to cut this final connecting surface, encountering such accidents, the entire or most of the diamond wire saw will be scrapped, resulting in unnecessary economic losses. Therefore, a diamond wire saw that is about to be scrapped is used, and even in the final cutting stage, even if such accidents occur, the economic losses caused are very small or limited.

According to different situations, the timing for replacement is generally to reduce the distance between the diamond wire saw and the saw slot cut to only 1.5~2.5m during horizontal cutting. Replace the diamond wire saw in use with a used diamond wire saw that is nearly discarded, and then continue to separate and cut the final connecting surface between the ore body and the separator.

This operation of replacing the used diamond wire saw with a new one is also required at the final stage of cutting the vertical surface or disassembling and reshaping the cutting. If the position of the guide wheel is installed properly, the used diamond wire saw can even directly cut through the cutting seam without leaving any connecting parts, making the cutting surface smooth and avoiding the occurrence of dents on one side and bumps on the other side when the final connecting parts are separated, which affects the flatness of the rough stone block.

The diameter of a diamond wire saw that is about to be scrapped is usually smaller than the diameter of the diamond wire saw in use, and it is not difficult to penetrate the saw gap formed by the new diamond wire saw. However, the operation of replacing a used diamond wire saw with a new one must be reliable, because if the used diamond wire saw fails to be threaded and the new diamond wire saw breaks away from the saw slot, it is very difficult, and sometimes even impossible, to threaded again.

Usually, the “relay type” threading method is used to complete the replacement of used/old and new diamond wire saws. Here are two “relay type” threading methods.

The first method is the connection traction method, which connects the cut new diamond wire saw and the old/used diamond rope saw with a connector/joint, and pulls the new rope with the old/used rope into the cutting seam. This method is safe, reliable, and foolproof.

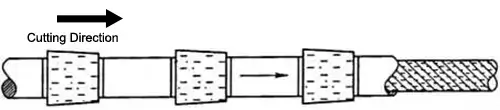

The second method is the superimposed driving method. Cut the diamond wire saw at a distance of about 2-3 m from the inlet of the diamond wire saw, so that the majority of the new rope is concentrated at the outlet. Inlay the old/used rope joint and the new rope joint together, overlap the diamond beads with the spacer layer, and use fine iron wire to firmly bind the overlapping part of the new and old/used rope. The outer diameter of the iron wire binding part must be smaller than the outer diameter of the diamond wire saw to prevent jamming. Tighten the new rope tightly against the saw seam, and firmly fix the old/used rope between the new rope and the cutting seam. While tightening the new rope, pull the new rope head at the outlet, bring the old/used rope in from the inlet, and pull it out together with the new rope from the outlet. The advantage of this method is that it saves one connector and one diamond bead, and is equally safe and reliable when operated properly. The following diagram is a schematic diagram of replacing a diamond wire saw with a superimposed driving method.

Linear Speed of Diamond Wire Saw

During stone mining, the linear speed of a diamond wire saw decreases as the hardness and cutting area of the cut stone increase. When the hardness of the stone is high and the cutting area is relatively large, the linear speed of the diamond wire saw should also be reduced. The cutting speed can only be improved if the cutting area is relatively small or the stone is soft. The following is the reference value of the line speed of the diamond wire saw when mining.

- In general, the linear speed of a diamond wire saw used for cutting marble is 38-40m/s. When cutting hard marble such as serpentine rock, the linear speed of a diamond wire saw is 32-38m/s.

- When mining and cutting soft granite, the linear speed of the diamond wire saw is 22-30m/s, and when mining and cutting hard granite, the linear speed of the diamond wire saw is 20-33m/s.

Therefore, the most suitable cutting linear speed should be determined based on the type of stone being mined, testing, and analyzing to determine the linear speed value.

In addition to stone mining, another application scenario of diamond wire saws is to shape rough stone blocks or cut the blocks into slabs. Like mining, the linear speed of diamond wire saws is also determined based on the type of stone, the length and size of rough stone block, and other actual situations. The recommended linear speed value for a diamond wire saw during normal cutting is:

- The linear speed of 24-26m/s is selected for cutting granite.

- The linear speed of 30-32m/s is selected for cutting marble.

The harder the stone or the longer the cutting area, the lower the linear speed of the diamond wire saw. If the linear speed is too high, it will cause the diamond saw to become blunt, while if it is too low, it will cause the diamond bead to become elliptical or conical.

Add Cooling Water

When the cutting process of diamond wire saw is different, the method of adding cooling water is also different. It is generally divided into two ways of adding cooling water: mining cutting and fixed diamond wire saw shaping cutting.

Add Cooling Water During Mining Cutting

During mining operations, 2-4 cooling water addition points are generally set based on the position and size of the cutting area, as well as the changes in the position of the sawing seam on the cutting surface.

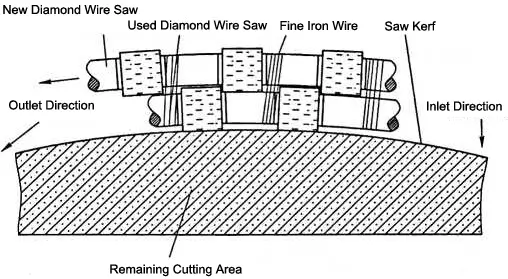

When cutting in a horizontal plane, it is usually necessary to arrange 3-4 cooling water addition points based on the size of the cutting area and the trajectory of the diamond wire saw surrounding the cutting surface.

- The main cooling water addition point is at the inlet of the diamond wire saw entering the ore body, and the cooling water at this point must be sufficient.

- A water addition point needs to be placed at the vertical drilling opening where it intersects with the horizontal hole.

- At the exit and corner of the diamond wire saw surrounding the horizontal plane, two auxiliary water addition points must also be placed.

The following picture is a schematic diagram of the cooling water addition points during the horizontal cutting of a diamond wire saw.

As the cutting surface moves, the two auxiliary water addition points located at the corners of the horizontal plane should move with the change of the cutting position of the diamond wire saw, especially the auxiliary cooling water adding point two. After the cutting surface moves, in order to ensure that the cooling water entering the vertical hole will not be lost, mud can be used to fill the saw gap formed by the horizontal cutting surface, so that this water flow can only flow out along the cutting position of the diamond wire saw and the ore body, improving the cooling effect.

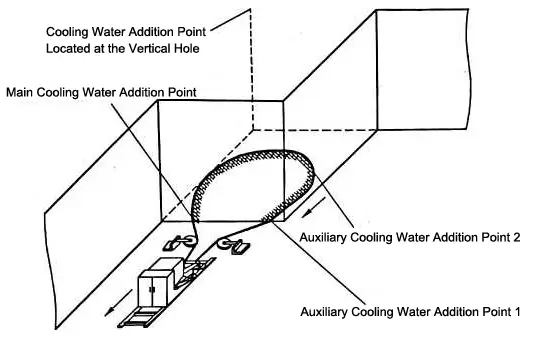

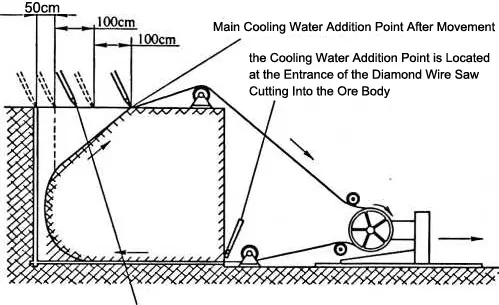

When cutting in a vertical plane, it is generally necessary to arrange 2-3 cooling water injection points.

- A water addition point is located at the entrance of the diamond wire saw entering the ore structure at the bottom. During normal cutting, the bottom cooling water addition point is basically fixed.

- A water addition point is located at the outlet of the diamond wire saw cutting the ore body at the top, and the cooling water addition point in the middle of the top moves with the change of the cutting position of the diamond wire saw, maintaining a suitable distance from the outlet of the diamond wire saw. Starting from the corner of the top outlet of the diamond wire saw, except for the first movement where the distance between the water addition point and the diamond wire saw outlet is not more than 50cm, it is appropriate to keep the distance between the water addition point and the diamond wire saw outlet less than 100cm for each subsequent movement.

- A replenishment water addition point can also be set at a distance of approximately 30-80cm from the exit of the diamond wire saw. The water addition point of supplementary cooling water is mainly used to supplement the cooling effect of the diamond wire saw inside the saw slot. Because the diamond wire saw moves at a high speed from bottom to top, the cooling water at the outlet of the saw may not fully enter the inside of the saw seam, and the cooling water at the inlet of the bottom diamond wire saw may not fully reach the inside of the saw seam. Especially when the cutting height is greater than 3m and the diamond wire saw inside the cutting seam is arc-shaped, it can cause a long section of the cutting seam inside the saw seam to have no cooling water, The consequences of dry grinding of diamond wire saws, which reduces their service life, can even lead to premature scrapping of diamond wire saws in severe cases. Because the water supply point is a certain distance from the outlet of the diamond wire saw, the water flow will not be affected by the movement of the diamond wire saw, and can flow into the deeper part of the saw gap as much as possible, improving the cooling state of the diamond wire saw cutting.

The following picture is a schematic diagram of cooling water addition points during the vertical cutting of a diamond wire saw.

The cooling water volume should be appropriate, excessive or insufficient water volume is not conducive to diamond wire saw cutting. How to determine whether the cooling water volume is just appropriate? When the cooling water sprayed at the outlet of the diamond wire saw is still liquid, the direct current of the water column at the outlet does not exceed 1.5~2 times the diameter of the diamond wire saw, and the cooling water sprayed at the outlet does not appear water vapor or foggy dust spray containing slag powder, the cooling water volume is appropriate.

If there is a burnt smell caused by overheating of rubber or plastic, it indicates that the cooling water is too small or missing, and long-term operation will damage or burn the diamond wire saw. When the cutting area is large, the water volume should not be too large because the cutting seam is deep and there is a lot of water in the middle, making it difficult to discharge the water. The resistance of the diamond saw increases, and excessive water volume can easily cause the diamond wire saw to slip, reducing the cutting effect.

When the diamond wire saw cutting work is in the final stage, or when performing shaping cutting, the cooling water becomes very easy to drain because the cutting seam is already small or has become open. At this time, the amount of cold water can be appropriately increased.

Add Cooling Water During Shaping Cutting

When using a fixed diamond wire saw for rough stone block shaping or stone slab cutting, due to the uneven surface of the stone rough block, in order to avoid fracture due to stress concentration during diamond wire saw cutting, and to obtain an accurate cutting surface, it is generally best to manually control the feed rate at the beginning of cutting. The feed rate should be 20%-30% lower than the normal value until the diamond wire saw completely cuts into the rough stone block, then switch the wire saw machine to automatic control feed rate mode.

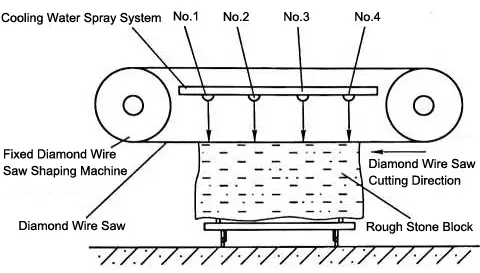

At the beginning of cutting, the cooling water spray points should be evenly spaced above the cutting seam between the diamond wire saw and the rough stone block. The arrangement of the cooling water spray points is shown in the following picture with points No.1 to No.4 being four equally spaced cooling water spray points.

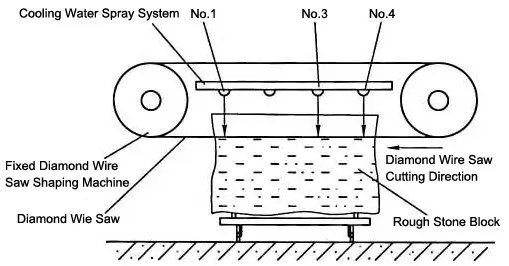

When the diamond wire saws cut into the rough stone block and perform with the normal cutting parameters, the No. 2 cooling water spray point can be turned off, and the position of the cooling water spray points is shown in the following figure.

During the cutting process of a fixed diamond wire saw, there is a requirement for cooling water. It is best to ensure that the diameter of the water flow at the outlet of the diamond wire saw is approximately 1.5-2 times the diameter of the diamond wire saw.

When operating, the supply of cooling water can be adjusted based on the sound of the diamond wire saw during cutting and the turbidity of the cooling water. In short, the supply of cooling water should be based on the fact that the water flow at the outlet of the diamond wire saw does not atomize stone powder and there is no burnt smell of plastic heat. It should be noted that it isn’t the more cooling water there is, the cutting performance better. Excessive cooling water can affect the self-sharpening of the diamond saw and cause it to slip in the saw gap, reducing cutting efficiency.

The position of the cooling water nozzle of the fixed diamond wire saw must be firmly fixed to prevent it from shifting due to cutting vibration or wind blowing, causing the diamond wire saw to work in a water shortage state. When there is a lack of cooling water supply, the diamond wire saw and injection layer will be quickly or immediately burned, and in severe cases, the entire diamond wire saw will be scrapped.

Maintenance of Diamond Wire Saw

In addition to using the diamond wire saw correctly, regular maintenance is also an important guarantee for improving the cutting efficiency and extending the service life of the diamond wire saw.

Inspection During Cutting Process

During the cutting process of diamond wire saw, it is necessary to check the wear status, sharpness of diamond beads, and whether the connector is normal when moving the cooling water position or stopping for other reasons.

After each cutting is completed, the operator must carefully inspect the wear condition of the connector of the diamond saw and its adjacent diamond beads, check whether the diamond beads have become excessively tapered or elliptical, and whether there is looseness between the diamond beads and the wire rope.

Common Problems and Repairs of Diamond Wire Saw

- If the connector and adjacent diamond beads are excessively worn, they must be cut off and replaced in a timely manner. Timely replacement of connectors can avoid accidents caused by sudden breakage of diamond wire saws and reduce downtime. The diamond wire saw for cutting marble should generally replace the connector every 50 square meters of area cut.

- When the diamond beads of plastic injection or rubber injection diamond wire saw become loose relative to the steel wire rope, if the number of loose diamond beads is not many and they are not far apart, and the effective length of the diamond wire saw is sufficient, it is best to cut off the part of the diamond wire saw where the loose diamond beads appear, and then reconnect the good diamond wire saw for use. If loose diamond beads are scattered throughout the entire diamond wire saw, the loose diamond beads can be broken and the exposed steel wire can be wrapped with waterproof tape, or the diamond wire saw can be cut off from the part where the loose diamond beads appear, removed, and connected with a new connector to continue using the diamond wire saw.

- If the diamond beads of the plastic or rubber injection diamond wire saw exhibit elliptical wear, it indicates that the diamond wire saw is no longer able to spin during the cutting process. If the ovality of the diamond bead is slight, the machine must be stopped to check the spin condition of the diamond wire saw, find the cause of the elliptical wear of the diamond bead, and adjust the process parameters such as the feed speed of the diamond wire saw to restore the diamond bead to its normal cylindrical shape. But when the ovality of the diamond bead is severe, the cutting and use of the diamond wire saw must be stopped immediately, the cause of the ovality of the diamond bead must be identified, and a repair plan for the diamond wire saw must be studied.

- The main reasons for the ovality wear of diamond beads in plastic or rubber injection diamond wire saws are: ① insufficient number of preloaded rotations or failure to perform preloaded rotations; ② The quality issues of the diamond wire saw itself, such as poor sealing quality between the diamond bead and the wire rope, and relative rotation caused by the lack of fixation between the diamond bead and the wire rope.

- The main reason for the ovality wear of the diamond beads in the spring type diamond wire saw is that during the assembly process of the diamond beads, the pre-pressure of the spring is too large, which tightly fixes the diamond beads on the wire rope, preventing them from rotating freely.

- If the diamond bead becomes conical, the usual reason is that the linear speed of the diamond wire saw is too low, which can be improved by increasing the linear speed during cutting.

In short, the problems that occur during the cutting process must be immediately identified and resolved in a timely manner before continuing the cutting operation of the diamond wire saw.

Maintenance

The main components of a spring type diamond wire saw are metal parts such as steel wire ropes, diamond beads, springs, connectors, and washers. If rust prevention and corrosion are not paid attention to during use, it will inevitably lead to premature damage and affect its service life. Regardless of the structure of the diamond wire saw, new diamond wire saws should be classified and stored in a dry environment. After using the diamond wire saw, it should be immediately rinsed with water, coiled, and hung in a dry place.

It is strictly prohibited to immerse the diamond wire saw after use in the mud and water of the mining face. When using it, attention must be paid to avoiding cutting or touching metal objects with the diamond wire saw, especially to prevent the diamond wire saw from cutting residual drill bits in the through hole.