- Diamond Saw Blades for Building Construction

- Cold Pressed Sintered Saw Blades

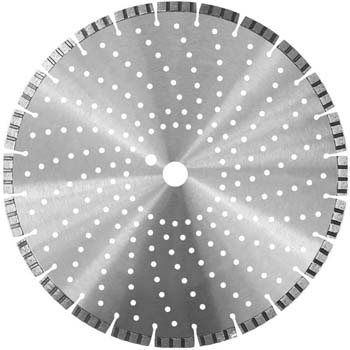

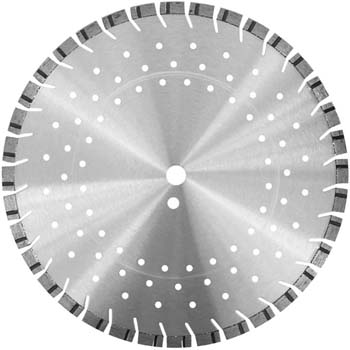

- Hot Pressed Sintered Saw Blades

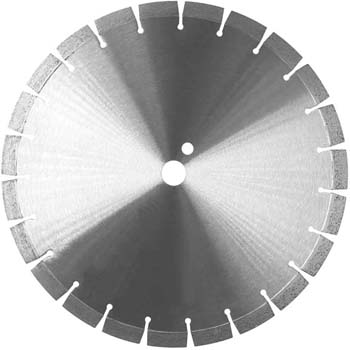

- Hot Pressed Sintered Segmented Saw Blade

- Hot Pressed Sintered Continuous Rim Saw Blade

- Hot Pressed Sintered Turbo Rim Saw Blade

- Hot Pressed Sintered Fine Turbo Rim Saw Blade

- Hot Pressed Sintered Super Thin Turbo Rim Saw Blade

- Hot Pressed Sintered Saw Blade With Protective Teeth

- Hot Pressed Sintered Saw Blade With Protective Square Teeth

- Hot Pressed Sintered Saw Blade With Protective Square Teeth

- Hot Pressed Sintered Turbo Rim Saw Blade With Protective Square Teeth

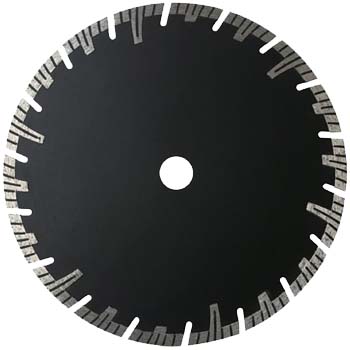

- Hot Pressed Sintered Segmented Turbo Saw Blade With Protective Teeth

- Hot Pressed Sintered Saw Blade With Square Protective Teeth

- Diamond Saw Blades for General Purpose

- Diamond Saw Blade for Concrete Cutting

- Diamond Saw Blades for Stone and Ceramic

- Tuck Point & Crack Chaser

Diamond circular saw blades are widely used in construction, cement pavement cutting, reinforced concrete wall cutting, stone cutting and many other professional fields. At the same time, in the DIY market, it is also one of the necessary tools.

Dymend has a complete production management system and produces diamond saw blades under strict quality standards. The product safety level has been certified by the German MPA standard and meets the European EN13236 quality standard.

Dymend has developed special cutting saw blades according to different cutting scenarios.

Diamond Saw Blades for Building Construction

In the construction process, there are various working conditions for cutting with diamond circular saw blades. It is common to use diamond saw blades to cut ceramic tiles, marble, granite, and concrete. The main purpose of such cutting is to cut off or shaping.

Cold Pressed Sintered Saw Blades

Cold pressing technology is a production process in sintered saw blades. Through this process, production efficiency can be greatly improved, energy loss can be reduced, and the finished saw blade products produced are highly versatile and cost-effective.

Cold Pressed Sintered Segmented Saw Blade

Cold pressed sintered segmented saw blade is a multi-application blade suitable for fast cutting a wide range of construction materials, such as masonry, brick, block, concrete, concrete pipe, stone, tile and so on.

- Fast cutting speed and no chipping.

- Best choice for DIY.

| Specifications of Cold Pressed Sintered Segmented Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/8//10/12 | 1.8/2.0 | 8 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7/8/9/10/12 | 1.8/2.0 | 8/9/10 | 20/22.23 | |

| 115 | 7/8/10/12 | 1.8/2.0/2.2 | 8/9 | 20/22.23 | |

| 125 | 7/8/10/12 | 1.8/2.0/2.2 | 8/9/10 | 20/22.23 | |

| 150 | 7/8/10/12 | 2.2/2.4 | 12 | 20/22.23/25.4 | |

| 180 | 7/8/10/12/15 | 2.2/2.4/2.6 | 14 | 20/22.23/25.4 | |

| 230 | 7/8/9/10/12 | 2.4/2.6/3.0 | 16/18 | 22.23/25.4 | |

| 250 | 8/10/12/15 | 2.8/3.0 | 18 | 20/22.23/25.4 | |

| 300 | 7/8/9/10/12/15 | 3.0/3.2 | 22 | 20/22.23/25.4 | |

| 350 | 8/9/10/12/15 | 3.2 | 24 | 20/22.23/25.4 | |

Cold Pressed Sintered Continuous Rim Saw Blade

Cold pressed sintered continuous rim saw blade is the best choice of the general-purpose blade for chip-free cutting, and suitable for cutting all types of ceramics, tile, porcelain, marble and masonry. Under the wet cutting condition, the diamond continuous rim blade performs better.

- Suitable for cutting a variety of materials.

- The cutting surface is smooth and the service life is good.

| Specifications of Cold Pressed Sintered Continuous Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 5/7/8/10/12 | 1.6/1.8/2.0 | / | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 5/7/8/10/12 | 1.6/1.8/2.0 | / | 20/22.23 | |

| 115 | 5/7/8/10/12 | 1.6/1.8/2.0 | / | 20/22.23 | |

| 125 | 5/7/8/10 | 1.6/1.8/2.0 | / | 20/22.23 | |

| 150 | 5/7/8 | 2.0/2.4 | / | 20/22.23/25.4 | |

| 180 | 5/7/8/10 | 1.8/2.0/2.2/2.3/2.4 | / | 16/20/22.23/25.4 | |

| 230 | 5/7/8/10 | 2.2/2.4/2.5 | / | 22.23/25.4 | |

| 250 | 6/7/10 | 1.8/2.0/2.8/3.0 | / | 22.23/25.4 | |

| 300 | 6/7/10 | 2.2/3.0 | / | 20/22.23/25.4 | |

| 350 | 7/10 | 3.2 | / | 20/22.23/25.4 | |

Cold Pressed Sintered Turbo Rim Saw Blade

Cold pressed sintered turbo rim saw blade is suitable for cutting marble, granite, concrete, brick and other masonry materials with a long cutting life.

- Efficient and smooth cutting performance.

- Suitable for wet and dry cutting both.

| Specifications of Cold Pressed Sintered Continuous Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/8/10/12 | 2.0/2.2/2.4 | / | 16/20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7/8/10/12 | 2.2/2.4 | / | 20/22.23 | |

| 115 | 7/8/10/12 | 2.0/2.2/2.4 | / | 20/22.23 | |

| 125 | 7/8/10/12 | 2.2/2.4/2.6 | / | 20/22.23 | |

| 150 | 7/10/12 | 2.8/4.0 | / | 20/22.23/25.4 | |

| 180 | 7/8/10/12 | 2.4/3.0/4.0 | / | 20/22.23/25.4 | |

| 230 | 5/7/8/10/12 | 2.6/3.0/3.2/4.0 | / | 22.23/25.4 | |

| 250 | 7/8/10/12 | 3.0/3.4/3.6/4.0 | / | 22.23/25.4 | |

| 300 | 8/10/12 | 3.2/3.8/4.0 | / | 20/22.23/25.4 | |

| 350 | 8/10/12 | 3.4/4.0 | / | 20/22.23/25.4 | |

Cold Pressed Sintered Fine Turbo Rim Saw Blade

Cold pressed sintered fine turbo rim saw blade is suitable for cutting marble, granite, concrete, brick, tile and other masonry materials with a long cutting life.

- Efficient and smooth cutting performance.

- Suitable for wet and dry cutting both.

| Specifications of Cold Pressed Sintered Fine Turbo Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/10 | 2.0/2.2 | / | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7 | 2.2 | / | 20 | |

| 115 | 7/10 | 2.4/2.5 | / | 20/22.23 | |

| 125 | 7/8/10 | 2.2/2.5 | / | 20/22.23 | |

| 150 | 7/10 | 2.8 | / | 20/22.23 | |

| 180 | 7/10 | 3.0 | / | 22.23/25.4 | |

| 230 | 7/9/10 | 3.2 | / | 22.23/25.4 | |

| 250 | 7/8 | 3.4 | / | 25.4 | |

| 300 | 8/10 | 3.8 | / | 20/22.23/25.4 | |

| 350 | 10 | 4.0 | / | 25.4 | |

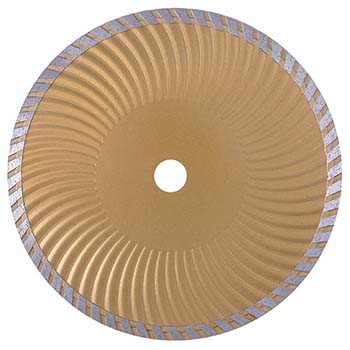

Cold Pressed Sintered Swirly Turbo Rim Saw Blade

Cold pressed sintered swirly turbo rim saw blade is suitable for cutting marble, granite, concrete and various construction materials.

- High cutting sharpness and fast production efficiency.

| Specifications of Cold Pressed Sintered Swirly Turbo Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7 | 2.2 | 8 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7 | 2.2 | 8 | 20/22.23 | |

| 115 | 7/10/12 | 2.5 | 8/12 | 22.23 | |

| 125 | 7/10 | 2.5 | 8 | 22.23 | |

| 150 | 7 | 2.8 | 10 | 20/22.23 | |

| 180 | 7/10 | 3.0 | 14 | 22.23/25.4 | |

| 230 | 7/9 | 3.2 | 16 | 22.23/25.4 | |

| 250 | 10 | 3.6 | 18 | 25.4 | |

| 300 | 8/10/12 | 3.8/4.0 | 22 | 20/22.23/25.4 | |

| 350 | 8/10/12 | 4.0 | 24 | 20/22.23/25.4 | |

Cold Pressed Sintered Turbo Wave Saw Blade

Cold pressed sintered turbo wave saw blade is suitable for cutting marble, granite, concrete, engineering brick and other masonry materials.

- Wave design of steel core guarantees smoother cutting with less chipping and better cooling.

- Suitable for wet and dry cutting both.

| Specifications of Cold Pressed Sintered Turbo Wave Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 8/10 | 2.2 | / | 16/20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 8/10 | 2.2 | / | 20/22.23 | |

| 115 | 7/8/10 | 2.4 | / | 20/22.23/25.4 | |

| 125 | 7/8/10 | 2.5 | / | 20/22.23 | |

| 150 | 7/8 | 2.8 | / | 22.23/25.4 | |

| 180 | 7/9/10 | 3.0 | / | 22.23/25.4 | |

| 230 | 7/8/9/10 | 3.2 | / | 22.23/25.4 | |

| 300 | 8/12 | 4.0 | / | 22.23/25.4 | |

Hot Pressed Sintered Saw Blades

In the production process of the sintered saw blade, the use of hot pressing technology can improve the overall rigidity and service life of the saw blade, and because it has a higher sintering temperature, the saw blade can obtain better quality, without edge breaking and splashing during use, so as to protect the safety of operators.

Hot Pressed Sintered Segmented Saw Blade

Hot press sintered segmented saw blade is designed for general purpose of all kinds of stone, brick, block and concrete materials.

- Fast cutting speed and no chipping.

| Specifications of Hot Pressed Sintered Segmented Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/8/10 | 1.6/1.8/2.0 | 8 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7/10/12 | 1.6/1.8 | 8/9/10 | 20/22.23 | |

| 115 | 7/10 | 1.8/2.0 | 8/9 | 20/22.23 | |

| 125 | 7/8/10/12 | 1.8/2.0/2.2 | 8/9/10 | 20/22.23/25.4 | |

| 150 | 7/10 | 2.0/2.2 | 12 | 22.23/25.4 | |

| 180 | 7/10 | 2.0/2.2/2.4 | 14 | 16/22.23/25.4 | |

| 230 | 7/10/12 | 2.0/2.4/2.6 | 16 | 22.23/25.4 | |

| 250 | 8/10 | 2.6 | 18 | 16/22.23//25.4 | |

| 300 | 7/10/12 | 2.8/3.0 | 22 | 20/22.23/25.4 | |

| 350 | 7/10/12 | 3.0/3.2 | 24 | 20/22.23/25.4 | |

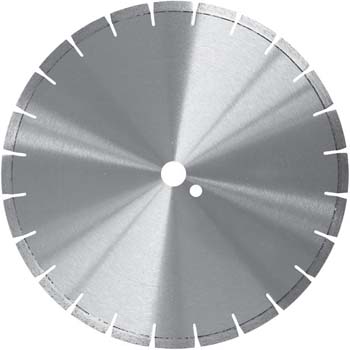

Hot Pressed Sintered Continuous Rim Saw Blade

Hot pressed continuous rim saw blade is the best choice of general purpose saw blade for perfect edge cutting.

- Suitable for cutting all types of ceramic tile, porcelain, marble and masonry.

| Specifications of Hot Pressed Sintered Continuous Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/10 | 12/1.4/1.6 | / | 16/20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 5/7/10 | 12/1.4/1.6 | / | 20/22.23 | |

| 115 | 5/7/8/10 | 1.2/1.4/1.6/1.8 | / | 20/22.23 | |

| 125 | 7/8/10 | 1.6/1.8 | / | 20/22.23 | |

| 150 | 7/8/10 | 1.4/1.6/1.8 | / | 20/22.23/25.4 | |

| 180 | 5/7/8/10 | 1.6/1.8/2.0 | / | 16/20/22.23/25.4 | |

| 230 | 7/8/10 | 1.6/1.8/2.0/2.2 | / | 22.23/25.4 | |

| 250 | 7/8/10 | 1.6/1.8/2.0/2.2/2.4 | / | 16/20/22.23//25.4 | |

| 300 | 7/10 | 2.0/2.2/2.4 | / | 20/25.4 | |

| 350 | 7/10/12 | 2.2/2.4 | / | 20/25.4 | |

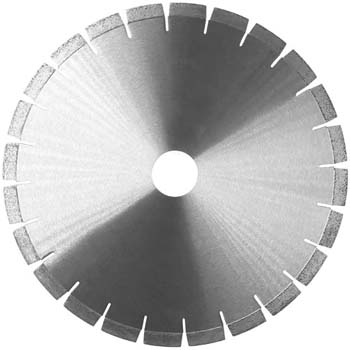

Hot Pressed Sintered Turbo Rim Saw Blade

Hot pressed sintered turbo rim saw blade is suitable for cutting all kinds of stones.

- Outstanding speed and long life for cutting.

- Dry/wet cutting.

| Specifications of Hot Pressed Sintered Turbo Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7 | 2.0 | / | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 8/12 | 2.0/2.2 | / | 20/22.23 | |

| 115 | 7/8 | 2.0/2.2 | / | 20/22.23 | |

| 125 | 7/8 | 2.2 | / | 20/22.23 | |

| 150 | 7 | 2.4 | / | 22.23 | |

| 180 | 7 | 2.6 | / | 22.23/25.4 | |

| 230 | 7 | 2.6/2.8 | / | 20/22.23/25.4 | |

| 300 | 7 | 2.8 | / | 20/22.23/25.4 | |

| 350 | 7 | 3.2 | / | 25.4 | |

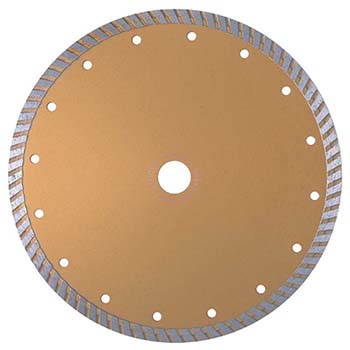

Hot Pressed Sintered Fine Turbo Rim Saw Blade

Hot pressed sintered fine turbo rim saw blade is suitable for cutting tiles, brick, concrete and other materials.

- Efficient and smooth cutting performance.

| Specifications of Hot Pressed Sintered Fine Turbo Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/8/9/10 | 1.6/1.8/2.0/2.2/2.4 | / | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7/10 | 2.0/2.2 | / | 20/22.23 | |

| 115 | 7/10/12 | 2.0/2.2/2.4/2.6 | / | 20/22.23 | |

| 125 | 7/8/9/10/12 | 2.0/2.4/2.6 | / | 20/22.23 | |

| 150 | 7/9/10/12 | 2.0/2.2/2.4/2.6/2.8 | / | 22.23/25.4 | |

| 180 | 7/9/10/12 | 2.2/2.4/2.5/2.6/2.8 | / | 22.23/25.4 | |

| 230 | 7/8/9/10/12 | 2.4/2.5/2.6/2.8 | / | 22.23/25.4 | |

| 250 | 7/9/10/12 | 2.4/2.6/2.8/3.0 | / | 22.23/25.4 | |

| 300 | 8/9/10/12 | 2.8/3.0/3.2 | / | 20/22.23/25.4 | |

| 350 | 8/10/12 | 3.2 | / | 20/22.23/25.4 | |

Hot Pressed Sintered Super Thin Turbo Rim Saw Blade

Hot pressed sintered super thin turbo rim saw blade is suitable for granite, marble, tile and ceramic.

- Fast cutting speed, small cutting gap and high cutting efficiency.

| Specifications of Hot Pressed Sintered Super Thin Turbo Rim Saw Blade | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/10 | 1.2/1.4 | / | 16/20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 7/10 | 1.2/1.4/1.6 | / | 20/22.23 | |

| 115 | 7/10/12 | 1.2/1.4/1.6 | / | 20/22.23 | |

| 125 | 7/8/10 | 1.2/1.4/1.6 | / | 20/22.23 | |

| 150 | 7 | 1.6/1.8 | / | 22.23/25.4 | |

| 180 | 7/10 | 1.6/1.8/2.0 | / | 22.23/25.4 | |

| 230 | 7 | 1.8/2.0/2.2 | / | 22.23/25.4 | |

| 250 | 7 | 2.4 | / | 25.4 | |

| 300 | 8 | 2.6 | / | 20/22.23/25.4 | |

| 350 | 8 | 2.8 | / | 20/22.23/25.4 | |

Hot Pressed Sintered Saw Blade With Protective Teeth

Hot pressed sintered saw blade is used for professional high speed cutting of most materials, including granite, marble, concrete, reinforced concrete, hard clay roof tiles, masonry and bricks.

- Wide range of applications.

- Safe and protected.

| Specifications of Hot Pressed Sintered Saw Blade With Protective Teeth | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 8 | 2.2 | 6 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 115 | 8 | 2.2 | 6 | 22.23 | |

| 125 | 8 | 2.4 | 6 | 22.23 | |

| 150 | 8 | 2.4 | 8 | 22.23 | |

| 180 | 8 | 2.6 | 8 | 22.23/25.4 | |

| 230 | 8 | 2.8 | 10 | 22.23/25.4 | |

| 250 | 9 | 2.8 | 10 | 22.23 | |

| 300 | 10 | 3.0 | 12 | 22.23/25.4 | |

| 350 | 10 | 3.2 | 12 | 22.23/25.4 | |

Hot Pressed Sintered Saw Blade With Protective Square Teeth

Hot pressed sintered saw blade with protective square teeth is used for professional high-speed cutting of most materials, including granite, marble, concrete, reinforced concrete, concrete products, engineering bricks, hard clay roof tiles, masonry products and bricks.

- Wide range of applications.

- Safe and protected.

| Specifications of Hot Pressed Sintered Turbo With Protective Teeth | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 115 | 9 | 2.4 | / | 22.23 | Product Customization and Brand OEM Are Available |

| 125 | 9 | 2.6 | / | 22.23 | |

| 150 | 9 | 2.6 | / | 22.23 | |

| 180 | 9 | 2.8 | / | 20/22.23/25.4 | |

| 230 | 9 | 3.0 | / | 22.23/25.4 | |

| 300 | 9 | 3.2 | / | 20/25.4 | |

| 350 | 9 | 3.4 | / | 20/25.4 | |

Hot Pressed Sintered Saw Blade With Protective Square Teeth

Hot pressed sintered saw blade with protective square teeth is used for professional high speed cutting of most materials, including granite, marble, concrete, reinforced concrete, concrete products, engineering bricks, hard clay roof tiles, masonry products and bricks.

- Wide range of applications.

- Safe and protected.

| Specifications of Hot Pressed Sintered Saw Blade With Protective Square Teeth | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7 | 2.0 | 9 | 20 | Product Customization and Brand OEM Are Available |

| 115 | 7 | 2.4 | 9 | 22.23 | |

| 125 | 7 | 2.4 | 9 | 22.23/25.4 | |

| 180 | 8 | 2.4 | 15 | 22.23/25.4 | |

| 230 | 8 | 3.0 | 18 | 22.23/25.4 | |

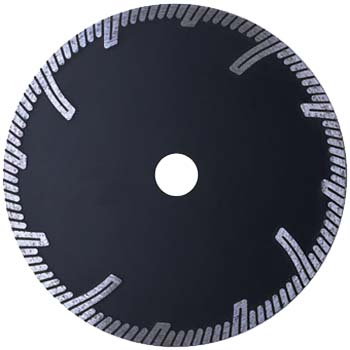

Hot Pressed Sintered Turbo Rim Saw Blade With Protective Square Teeth

Hot pressed sintered turbo rim saw blade with protective square teeth is used for cutting granite, marble, concrete, reinforced concrete, bricks, masonry, etc.

- Wide range of applications.

- Safe and protected.

| Specifications of Hot Pressed Sintered Turbo Rim Saw Blade With Protective Square Teeth | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7 | 2.0 | 9 | 20 | Product Customization and Brand OEM Are Available |

| 115 | 7 | 2.4 | 9 | 22.23 | |

| 125 | 7 | 2.4 | 9 | 22.23/25.4 | |

| 180 | 8 | 2.4 | 15 | 22.23/25.4 | |

| 230 | 8 | 3.0 | 18 | 22.23/25.4 | |

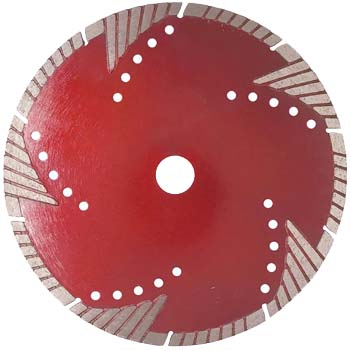

Hot Pressed Sintered Segmented Turbo Saw Blade With Protective Teeth

Hot pressed sintered segmented turbo with protective teeth is used for professional high-speed cutting of granite, marble, concrete, reinforced concrete, engineering bricks, hard clay roof tiles, masonry products and bricks.

- Wide range of applications.

- Safe and protected.

| Specifications of Hot Pressed Sintered Segmented Turbo With Protective Teeth | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 125 | 8 | 2.5 | 9 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 180 | 8 | 2.8 | 15 | 22.23 | |

Hot Pressed Sintered Saw Blade With Square Protective Teeth

Hot pressed sintered saw blade with square protective teeth is used for professional high-speed cutting of most materials, including granite, marble, concrete, reinforced concrete, engineering bricks, hard clay roof tiles, masonry products and bricks.

| Specifications of Hot Pressed Sintered Saw Blade With Square Protective Teeth | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 8/10 | 2.0 | 8 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 115 | 8 | 2.4 | 9 | 22.23 | |

| 125 | 7 | 2.4 | 9 | 22.23/25.4 | |

| 150 | 8 | 2.4 | 12 | 22.23 | |

| 180 | 8 | 2.4 | 15 | 22.23 | |

| 230 | 7 | 3.0 | 18 | 22.23/25.4 | |

Diamond Saw Blades for General Purpose

General purpose saw blades include two types of laser welding and silver welding, which are suitable for the cutting of various stone and concrete products. The common processing method is the cutting and trimming of plate corners and bevels. The early welding method was welding with silver welding pieces, and later the technology was developed to laser welding, which can greatly enhance the welding strength between the segments and the blank, improving safety during working.

Laser Welded Diamond Saw Blades for General Purpose

Laser welded diamond saw blades for general purpose materials which are designed for free cutting and dry cutting, such as masonry materials, stone, concrete and abrasive materials, and so on.

| Specifications of Laser Welded Segmented Saw Blade for General Purpose | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 7/8/10 | 2.2 | 8 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 10/12 | 2.2/2.4 | 8/9 | 20 | |

| 115 | 7/8/10/12 | 2.2/2.4 | 8/9 | 20/22.23 | |

| 125 | 7/9/10/12 | 2.2/2.4 | 9/10 | 22.23 | |

| 150 | 7/8/10 | 2.4 | 12 | 22.23/25.4 | |

| 180 | 7/8/10/12 | 2.4/2.8 | 14 | 22.23/25.4 | |

| 230 | 7/8/9/10/12 | 2.5/2.6/2.7/2.8/3.2 | 15/16 | 22.23/25.4 | |

| 250 | 7/10/15 | 2.5/2.8/3.0 | 17 | 22.23/25.4 | |

| 300 | 7/8/9/10/12/15 | 2.8/3.0/3.2 | 20 | 20/22.23/25.4 | |

| 350 | 8/10/12 | 2.6/2.8/3.0/3.2/3.4 | 24 | 20/25.4 | |

| 400 | 8/10/12 | 3.2/3.4/3.6 | 28 | 20/25.4 | |

| 450 | 8/10/12 | 3.4/3.6 | 32 | 20/25.4 | |

| 500 | 7/10/12 | 3.2/3.4/3.8 | 36 | 25.4 | |

| 600 | 7/10/12 | 4.0/4.2/4.4 | 42 | 25.4 | |

Silver Welded Diamond Saw Blades for General Purpose

Silver weld diamond saw blades for general purpose are designed for heavy-duty cutting granite, marble, natural stone, all concrete materials and asphalt. Its high-frequency electrial brazing process and tough segment design provide for exceptional performance.

| Specifications of Silver Welded Blades for General Purpose | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 250 | 10 | 2.8 | 16 | 25.4/50 | Product Customization and Brand OEM Are Available |

| 300 | 10 | 2.8/3.0/3.4 | 20 | 25.4/50 | |

| 350 | 10/12/15 | 3.0/3.2/3.4 | 23/24 | 25.4/50/60 | |

| 400 | 10/12/15 | 3.4/3.6 | 27/28 | 25.4/50/60 | |

| 450 | 10/12/15 | 3.6/3.8/4.0 | 31/32 | 25.4/50/60 | |

| 500 | 10/12 | 3.6/3.8/4.0 | 34/36 | 25.4/50/60 | |

| 550 | 10/12 | 4.0 | 38 | 25.4 | |

| 600 | 10/12 | 4.0/4.2/4.4 | 42 | 25.4/50/60 | |

| 650 | 10/12 | 4.4/4.8 | 46 | 25.4/50/60 | |

| 700 | 10/12 | 4.8 | 48 | 50/60 | |

Diamond Saw Blade for Concrete Cutting

Concrete cutting saw blades are all laser welded to ensure operational safety. They are mainly used for cutting floors, roads, building walls, parking lots, runways, etc. They are mainly used in wet-cutting environments. The processed materials include reinforce concrete, green concrete, asphalt, etc.

Laser Welded Blades for Asphalt & Green Concrete

Laser welded blades for asphalt and green concrete are designed for abrasive materials such as asphalt, green concrete, and asphalt over concrete. It contains tough wear-resistant bonds and hard metal protections or wedged diamond segments against under-cutting.

| Specifications of Laser Welded Blades for Asphalt & Green Concrete | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 180 | 10 | 2.4 | 14 | 25.4 | Product Customization and Brand OEM Are Available |

| 230 | 10 | 2.5/2.8 | 15 | 22.23 | |

| 300 | 10/12/15 | 3.0/3.2 | 18 | 20/25.4 | |

| 350 | 7/8/10/12/15 | 3.2 | 21 | 20/25.4 | |

| 400 | 8/10/12 | 3.2/3.4 | 24 | 20/25.4 | |

| 450 | 7/8/12 | 3.2/3.6/4.0 | 27 | 25.4 | |

| 500 | 10/12 | 3.8 | 30 | 25.4 | |

| 600 | 10/12 | 4.0/4.2/4.4 | 36 | 25.4 | |

Laser Welded Blades for Cured Concrete

Laser welded blades for cured concrete are laser welded and specially designed for cutting cured concrete with various aggregates and heavy reinforcement.

| Specifications of Laser Welded Blades for Cured Concrete | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 105 | 12 | 2.2 | 9 | 20/22.23 | Product Customization and Brand OEM Are Available |

| 110 | 12 | 2.2/2.4 | 9 | 20 | |

| 115 | 12 | 2.2/2.4 | 10 | 20/22.23 | |

| 125 | 12 | 2.2/2.4 | 11 | 22.23 | |

| 150 | 12 | 2.2/2.4 | 14 | 22.23/25.4 | |

| 180 | 12 | 2.4/2.8 | 17 | 22.23/25.4 | |

| 230 | 12 | 2.6/2.8 | 22 | 22.23/25.4 | |

| 250 | 12 | 2.8/3.0 | 24 | 22.23/25.4 | |

| 300 | 12 | 2.8/3.0/3.2 | 30 | 22.23/25.4 | |

| 350 | 12 | 3.2 | 36 | 20/22.23/25.4 | |

| 400 | 12 | 3.4 | 42 | 20/25.4 | |

| 450 | 12 | 3.6 | 48 | 20/25.4 | |

Diamond Saw Blades for Stone and Ceramic

Among building materials, granite, marble, and ceramics are the three most commonly used materials, and diamond saw blades are commonly used tools for processing these materials. The welding process includes laser welding and silver welding.

Laser Welded Blades for Granite

Laser welded blades for granite are used for high-speed economical cutting of various granite.

| Specifications of Laser Welded Blades for Granite | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 115 | 10 | 2.2 | 9 | 22.23 | Product Customization and Brand OEM Are Available |

| 125 | 10 | 2.2/2.4 | 10 | 22.23 | |

| 150 | 10 | 2.4 | 12 | 22.23 | |

| 180 | 10 | 2.4 | 14 | 22.23 | |

| 230 | 10 | 2.5/2.6/2.8 | 16 | 22.23 | |

| 250 | 7/10 | 2.5/2.8 | 17 | 22.23/25.4 | |

| 300 | 7/8/10/12/15 | 3.0/3.2 | 20 | 20/22.23/25.4 | |

| 350 | 10/12 | 3.2/3.4 | 24 | 20/25.4 | |

| 400 | 8/10/12 | 3.2/3.4/3.6 | 28 | 20/25.4 | |

| 450 | 8/10/12 | 3.4/3.6 | 32 | 20/25.4 | |

| 500 | 7/10/12 | 3.2/3.4/3.8 | 36 | 25.4 | |

| 600 | 7/10/12 | 4.0/4.2/4.4 | 42 | 25.4 | |

Silver Welded Blades for Granite(Sandwich Segment)

- Silent and non-silent steel cores are available.

- For high speed economical cutting of granite and marble.

- The segment is sandwich type.

- It has a long cutting life and excellent cutting performance.

| Specifications of Silver Welded Blades for Granite(Sandwich Segments) | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 350 | 15 | 3.2 | 24 | 60 | Product Customization and Brand OEM Are Available |

| 370 | 15 | 3.2 | 24 | 50/60 | |

| 400 | 15 | 3.4 | 28 | 60 | |

| 420 | 15 | 3.4 | 28 | 60 | |

| 450 | 15 | 3.6 | 30 | 60 | |

Silver Welded Blades for Marble

- Silent and non-silent steel cores are available.

- The fan-shaped segment is designed for marble.

- The narrow segment gap provides ideal edge trimming quality.

| Specifications of Silver Welded Blades for Marble | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 250 | 8/10 | 2.6/2.8 | 16 | 25.4/60 | Product Customization and Brand OEM Are Available |

| 300 | 8/10 | 2.2/2.8 | 22 | 25.4/50/60 | |

| 350 | 8/10 | 2.8/3.0 | 25 | 25.4/60 | |

| 356 | 8/10 | 2.8/3.0 | 25 | 25.4/50/60 | |

| 400 | 8/10 | 3.0/3.2 | 30 | 60 | |

| 450 | 8/10 | 3.0/3.2 | 32 | 60 | |

Silver Welded Blades for Ceramic

- Designed for cutting ceramic without chipping.

- The blade has good sharpness and high efficiency.

| Specifications of Silver Welded Blades for Ceramic | |||||

|---|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Bore(mm) | Note | |

| Height | Thickness | ||||

| 300 | 8/12 | 2.2 | 22 | 25.4/50/60 | Product Customization and Brand OEM Are Available |

| 350 | 10/12 | 2.4/2.8 | 25 | 25.4/50/60 | |

| 356 | 8/10 | 2.4/2.8 | 25 | 50 | |

| 400 | 8/10 | 2.8/3.0 | 30 | 50/60 | |

| 450 | 8/10 | 3.0 | 32 | 50 | |

| 500 | 8/10 | 3.2 | 36 | 50 | |

Tuck Point & Crack Chaser

Tuck Point

- The wide segments are designed for mortared expansion joints and slotting granite, marble, concrete, etc.

- It provides for fast and efficient removal of morter joints in preperation for sealing.

| Specifications of Tuck Point with Wide Segment | ||||

|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Note | |

| Thickness | Height | |||

| 105 | 6.4 | 7/10 | 8 | Product Customization and Brand OEM Are Available |

| 115 | 6.4 | 7/10 | 8 | |

| 125 | 6.4 | 7.5/10/12 | 9 | |

| 150 | 6.4 | 10 | 12 | |

| 180 | 6.4 | 7/10 | 14 | |

| 230 | 6.4 | 7.5/10 | 16 | |

Turbo Tuck Point

- Designed for repairing grout, cleaning and routing cement joints.

| Specifications of Turbo Tuck Point | ||||

|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Note | |

| Thickness | Height | |||

| 115 | 6.4 | 10 | 8 | Product Customization and Brand OEM Are Available |

| 125 | 6.4 | 10 | 9 | |

| 150 | 6.4 | 10 | 10 | |

Crack Chaser

- V-shaped segments are designed for quick repair works of concrete cracks by smooth grooving.

| Specifications of Crack Chaser for Quick Repair Works | ||||

|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Note | |

| Thickness | Height | |||

| 105 | 6.4/9.5 | 10 | 8 | Product Customization and Brand OEM Are Available |

| 115 | 6.4/9.5 | 10 | 9 | |

| 125 | 6.4/9.5 | 10 | 10 | |

| 180 | 9.5 | 10 | 14 | |

Turbo Crack Chaser

- It can provide constant depth with angle cutting on marble, granite, brick, concrete and other materials.

| Specifications of Crack Chaser for Quick Repair Works | ||||

|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Note | |

| Thickness | Height | |||

| 105 | 9.5 | 10 | / | Product Customization and Brand OEM Are Available |

| 115 | 9.5 | 10 | / | |

| 125 | 9.5 | 10 | / | |

| 180 | 9.5 | 10 | / | |

Sandwich Tuck Point(Double)

- Used for soft or medium concrete, brick, block, masonry.

- Economic tuck point consists of two segmented(turbo) cutting blades.

| Specifications of Sandwich Tuck Point With Double Structure Design | ||||

|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Note | |

| Thickness | Height | |||

| 105 | 6.4 | 7/10 | 8 | Product Customization and Brand OEM Are Available |

| 115 | 6.4 | 7/10 | 8 | |

| 125 | 6.4/9.5 | 7/10 | 9 | |

| 150 | 6.4 | 7/10 | 12 | |

| 180 | 6.4 | 7/10 | 14 | |

Sandwich Tuck Point(Treble)

- Used for soft or medium concrete, brick, block, and masonry.

- Economic tuck point consists of three segmented cutting blades.

| Specifications of Sandwich Tuck Point With Treble Structure Design | ||||

|---|---|---|---|---|

| Diameter(mm) | Segment Dimension(mm) | Segments Number | Note | |

| Thickness | Height | |||

| 115 | 9.5 | 10 | 8 | Product Customization and Brand OEM Are Available |

| 125 | 9.5 | 10 | 9 | |