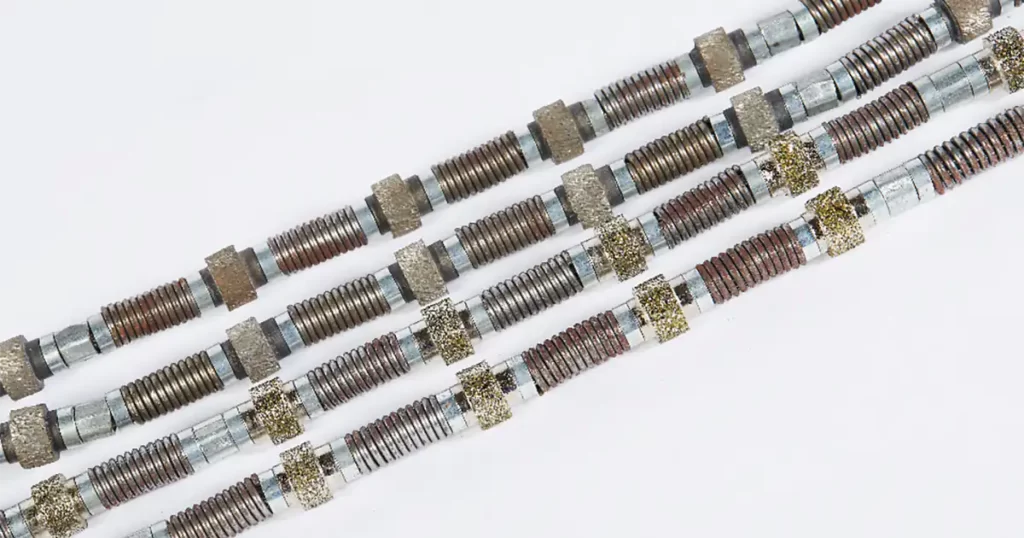

The connector of diamond wire saw is also called steel coupling or joint. Because the diamond wire saw is linear, it must be connected into a closed loop through the connector to carry out the cutting operation. The diamond wire saw of different applications should be connected with connectors of different structures. The quality of the connector directly affects the normal work and service life of the diamond wire saw. At present, the commonly used diamond wire saws are connected by connectors with friction type, that is, the special crimping tool is used to press the connector and the wire rope of the diamond wire saw together, then the connector and the diamond wire saw is connected by the static friction. This connection method is applicable to all connectors. There is also a brazed connection method, that is, the brazed connection between the wire rope and the connector. This connection method is mostly used for removable threaded connectors.

Types of Diamond Wire Saw Connectors

According to the structures, the connector can be divided into metal sleeve fixed connector, single thread connector, double thread connector and special mechanical removable connector(articulated connector).

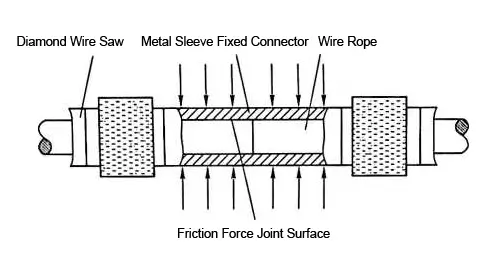

Metal Sleeve Fixed Connector

The metal sleeve fixed connector is a disposable fixed connector, which is the most commonly used diamond wire saw connector. The following picture is the structural diagram of the metal sleeve fixed connector. When using, the two ends of the wire rope shall be inserted from the two ends of the metal sleeve respectively, and the insertion distance shall be half of the length of the connector. Use the crimping tool to press the connector and the wire rope, and connect them directly by the static friction between the wire rope and the internal structure of the connector. In order to increase the binding force, the inner hole of the metal sleeve can be made into a shallow spiral. There are two types of materials for metal sleeve fixed connectors: copper and steel. Copper material connectors are often used to cut soft stones such as marble and limestone, while steel material connectors are often used to cut hard stones such as granite.

The metal sleeve fixed connector has the advantages of simple structure, stable and reliable connection and low cost. The disadvantage is that with the reduction of the cutting area, the length of the diamond wire saw sometimes needs to be cut, and the diamond wire saw must be cut at the part of connector every time. At least one diamond bead will be wasted every time, and the diamond wire saw will also be shortened. Especially when connecting the spring-type diamond wire saw, the corresponding diamond beads, springs, washers and other parts need to be penetrated, which is troublesome to operate.

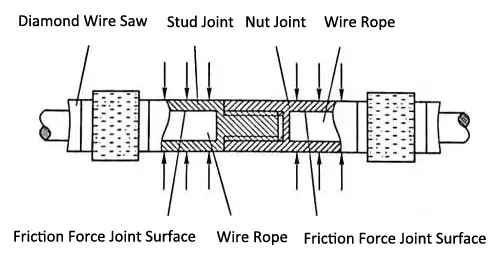

Single Thread Connector

The single thread connector is a detachable diamond wire saw connector. The following picture is the structural diagram of the single thread connector. The single thread connector is composed of a stud joint and a nut joint. The wire rope is inserted at one end of the joint, and the same pressing connection principle as the metal sleeve fixed connector is adopted, which is based on static friction combination. The stud and nut can also be combined with the wire rope by brazing to increase the connection firmness between them. Because the diamond wire saw operates in the right-handed direction when cutting, only when the combination direction of the stud and nut is made into the left-handed direction can it ensure that when the diamond wire saw moves, the threaded connector will be tightened better and will not loosen.

The advantages of single thread connector are fast and reliable connection and easier operation. A stud and nut are fixed at both ends of each section of diamond wire saw to realize the disassembly and combination of multiple diamond wire saws. Each time the diamond wire saw is increased or decreased according to the unit length, it is only necessary to remove the diamond wire saw in the middle section of the unit length and combine the remaining diamond wire saw again to complete the length adjustment of the bead rope. Because there is no need to cut the diamond wire saw, the length of the diamond wire saw will not be lost. Single thread connectors are usually used for cutting soft stones such as marble, limestone and travertine.

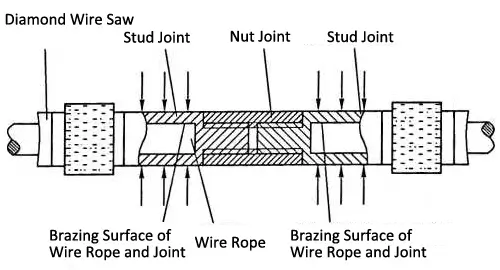

Double Thread Connector

The double thread connector is also a detachable and reusable fixed connector. Its structure is basically the same as the single thread connector, except that the two ends of the wire rope are all connected with stud joints, and a nut joint is added in the middle. The connecting thread of the joint is still left-handed. The wire rope and stud joint are connected by brazing, which ensures the reliability of the connection between the joint and the wire rope, and the connection is also very convenient. The following picture is the structural diagram of the double thread connector. Because most stone mines do not have brazing equipment, this connector is generally used in large stone mining enterprises.

The double thread connector can also adopt the structure with nuts at two terminals and stud in the middle. This is the opposite structure type to the above picture, which will connect the wire rope to the nuts at two terminals. There is also a special double thread structure connector. The joints at the two terminals are stud structure, and the nuts in the middle are two diamond beads connected in series. The advantage of this connector structure is that the diamond beads on the outer surface of the connector nut directly work in cutting the stone, so that the life of the connector nut is the same as that of the diamond wire saw, and the premature abrasion damage of the connector nut is avoided.

Because the rotation direction of the double thread connector is opposite to that of the diamond wire saw, the double thread connector will be connected very tightly during the cutting process of the diamond wire saw, so some difficulties will be encountered during the disassembly. In order to prevent the connector from being damaged during disassembly, special tools can be used to help complete the disassembly.

Articulated Connector

The articulated connector adopts an ingenious mechanical chain connection structure. When disassembling, bend the connector 90° to complete the disassembly and separation of the connector. Because the diamond wire saw cannot bend 90° during cutting stone or concrete, the joint will not break off. Both terminals of the articulated connector and the wire rope are connected by brazing. Because the mechanical structure and manufacturing process of the articulated connector is complex, in order to prevent the articulated connector deformation caused by crimping connection and affect the reliability of its disassembly and assembly operation, the method of crimping the connector with wire rope by static friction is rarely used.

The advantages of the articulated connector are that the material is better, not easy to wear, and the disassembly can be completed without any tools. The disassembly is more convenient, and the joint will not be damaged. However, as a disposable accessory, the manufacturing and use cost of the articulated connector is relatively high, so this connector should be used for the diamond wire saw with long service life as far as possible.

How to Select the Connector of Diamond Wire Saw

Different cutting processes of stone or concrete shall be selected with different diamond wire saw connectors. Dymend Tools summarized the following recommendations.

① The copper metal sleeve fixed connector, thread connector and articulated connector are generally used for the connection of diamond wire saw for marble, limestone, travertine and other soft stone mines.

② The steel metal sleeve fixed connector is generally used for the connection of diamond wire saw in the mining of granite and other hard stones.

③ For diamond wire saw connectors used for shaping cutting or cutting stone slab/plate, especially for special-shaped cutting through fixed equipment, because diamond wire saw needs to bear relatively large tension, the steel metal sleeve fixed connector is generally used to improve the processing accuracy of stone products.

④ The connection of sintered diamond wire saw used for granite mining generally uses steel metal sleeve fixed connector.

⑤ The spring type diamond wire saw used for marble mining can use detachable thread connector.

⑥ The thread or articulated detachable connector can be used for the connection of diamond multi-wire saw, fixed reshaping or special-shaped diamond wire saw for processing soft stone, so as to prevent the consistency of tension of the whole set of diamond wire saw from being affected by the different length of each diamond wire saw when disassembling the diamond wire saw for many times.

⑦ When using the diamond wire saw to cut the closed special-shaped stone products, it is better to use the detachable thread connector or the articulated connector.

How to Crimp the Connector of Diamond Wire Saw

The diamond wire saw connector is usually crimped with hydraulic tools. The most commonly used tool is the hydraulic pincer.

Regardless of the connector structure, when the static friction connection method is adopted between the diamond wire saw connector and the wire rope, the pull-off force of the connector and the wire rope must reach or exceed 2.5-3 times of the tension of the diamond wire saw when cutting concrete or stone. According to the different applications of the diamond wire saw, the pull-off force of the connector must not be less than 5000N. Therefore, the hydraulic tool should have enough pressure to crimp the diamond saw connector well.

After many field tests and customer feedback, Dymend Tools summarized the following values.

① When crimping the connector of the diamond wire saw for marble cutting, hydraulic tools with a pressure of 100kN shall be used.

② When crimping the connector of the diamond wire saw for granite cutting, the pressure of crimping tool must reach 200kN to ensure that the connector can be reliably connected with the wire rope.

Service Life of Diamond Wire Saw Connector

Usually, the longer the life of the diamond wire saw, the better, but the connector of the diamond wire saw is not.

In addition to the need to replace the connector in case of normal wear and damage, the continuous service life of the connector of the diamond wire saw shall not exceed 24h at most. If this time is exceeded, the diamond wire saw can easily be detached or broken from the connector, resulting in personal accidents or equipment damage. Therefore, the service life/duration of the diamond wire saw connector should be recorded and replaced in time.

Conclusion

Although the diamond wire saw connector is only a small accessory of the diamond wire saw, the selection of a suitable connector is one of the important keys to the normal use of the diamond wire saw.

Select different connector materials for different stone hardness, select different connector structures for different cutting conditions, and know how to replace connectors and timely replace connectors. These are the qualities that a skilled engineer should have.